- Home

- >

- News

- >

- Company news

- >

- Considerations for Selecting and Using Apron Feeders in Stone Crusher Plants

Considerations for Selecting and Using Apron Feeders in Stone Crusher Plants

The Apron Feeder plays an important role in the production process of a Stone Crusher Plant by providing an even and continuous flow of material from the hopper or stockpile to the receiving unit. There are several key factors to consider when selecting and using an apron conveyor:

1. feeding capacity: according to the production demand of Stone Crusher Plant, choose Apron Feeder with suitable feeding capacity, which should match the processing capacity of the crusher to ensure the smooth operation of the whole production line. When necessary, heavy duty apron feeder should be selected.

2. Material Characteristics: Different materials have different characteristics such as particle size, humidity, hardness, etc. Choose the Apron Feeder that suits the material characteristics. Select the Apron Feeder that suits the material characteristics to ensure that it can effectively convey and feed the material. When the moisture content is high, it is not suitable to choose vibrating feeder, but need to use belt feeder or plate feeder.

3. Wear resistance: Due to the harsh working environment of a Stone Crusher Plant, the Apron Feeder needs to have good wear resistance. Choose equipment made of wear-resistant materials to extend its service life.

4. Feeding accuracy: The feeding accuracy of the Apron Feeder is critical to the productivity and quality of the Stone Crusher Plant. Select equipment with precise feeding control system to ensure the stability and uniformity of material feeding. Generally, choose apron conveyor with variable frequency motor drive can effectively control the feeding speed.

5. ease of maintenance: consider the ease of maintenance of the equipment, choose the apron conveyor easy to clean, overhaul and replace parts, which can reduce maintenance costs and downtime.

(Specialized scrapers can be fitted to the Apron Feeder's chain plates.)

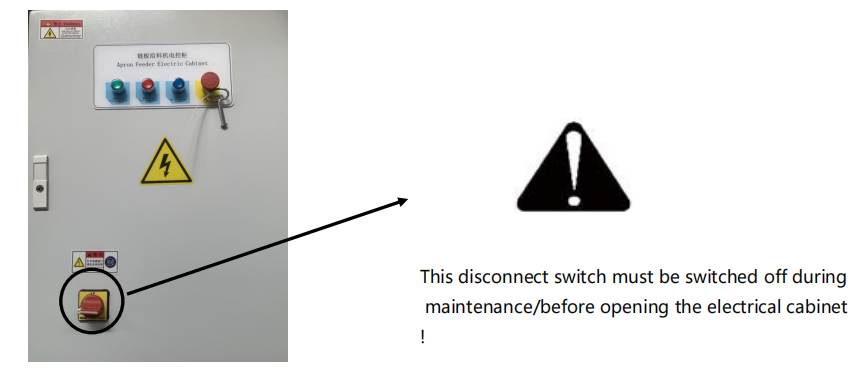

6. safety performance: make sure the selected Apron Feeder has good safety performance, including guards, emergency stop button, etc., to protect the safety of operators.

7. Manufacturer's reputation and service: Choose a company with rich experience in the industry to ensure that it has good quality and reputation. At the same time, understand the after-sales service and technical support provided by the manufacturer to guarantee the normal operation and maintenance of the equipment.

◆In conclusion, when choosing and using Apron Feeder, you need to comprehensively consider the specific needs of Stone Crusher Plant, equipment performance and use of precautions and other factors. Reasonable selection and correct use will help improve productivity, reduce costs and ensure stable operation of the production line.