-

Steel Silo

CAFU Machinery's cement silo, after professional design, adopts modular production and bolt assembly with good sealing performance. It is mainly used for storing cement, fly ash, mineral powder and other powders, which is widely used in wharves, cement factories, concrete mixing stations, construction sites and other places. We also sale grain silo.

-

Auxiliary Steel Structure

The steel structure support frame for the equipment is manufactured by factory modular processing, arranged in coded packaging, and transported to the project site by container for installation. The modular steel structure prefabricated products are used in the brackets of equipment in various industries to play a stabilizing and fixing role. The products are well-made and the welds are beautiful. The product parts are processed by CNC cutting equipment, which can meet the quality requirements of various industries for precise size control. The appearance of the steel structure is treated by shot blasting and sandblasting, and then sprayed with paint with a high anti-rust level, which can ensure that the appearance of the product is maintenance-free for a long time.

-

Bag Filter

Bag filters are widely used in building materials, metallurgy, chemical, thermal power and other industries. The pulse jet bag filter is used in silo roofs, building materials processing production lines, mining production lines, furniture factory production lines and other occasions, and has a good ash collection and dust collection effect. The bag filter adopts cloth bag (polyester needle felt, waterproof and oil proof) to filter dust, with high dust removal efficiency; adopts medium and high-pressure gas (0.4~0.6MPa) to blow the cloth bag to remove the dust on the cloth bag and achieve the purpose of recycling the cloth bag.

-

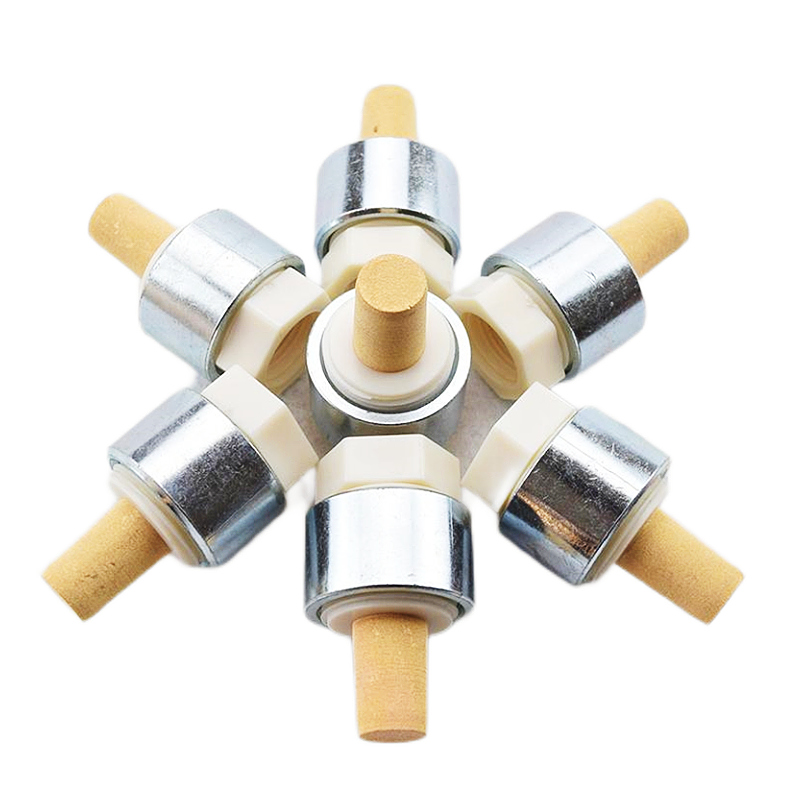

Silo Accessories

Silo accessories usually need to use flow aid gas nozzle, level meter, silo top explosion-proof valve, butterfly valve, vibration motor, gate valve, vibration hopper, etc.

-

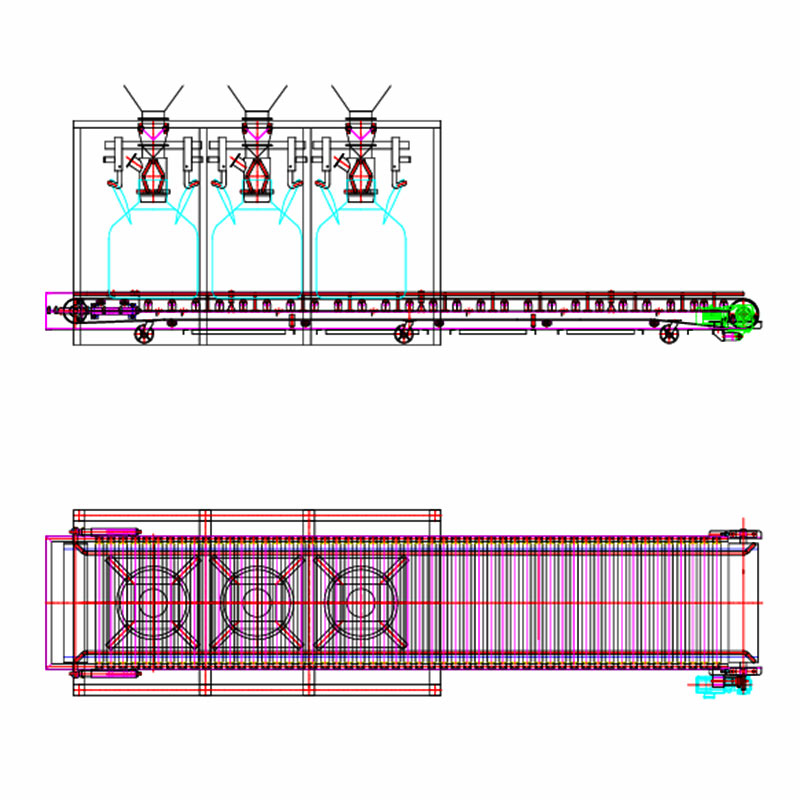

Bulk Material Tons Packaging System

CAFU offers customization ton packaging systems for a wide range of bulk material handling, designed to meet the unique needs of a variety of industries.

-

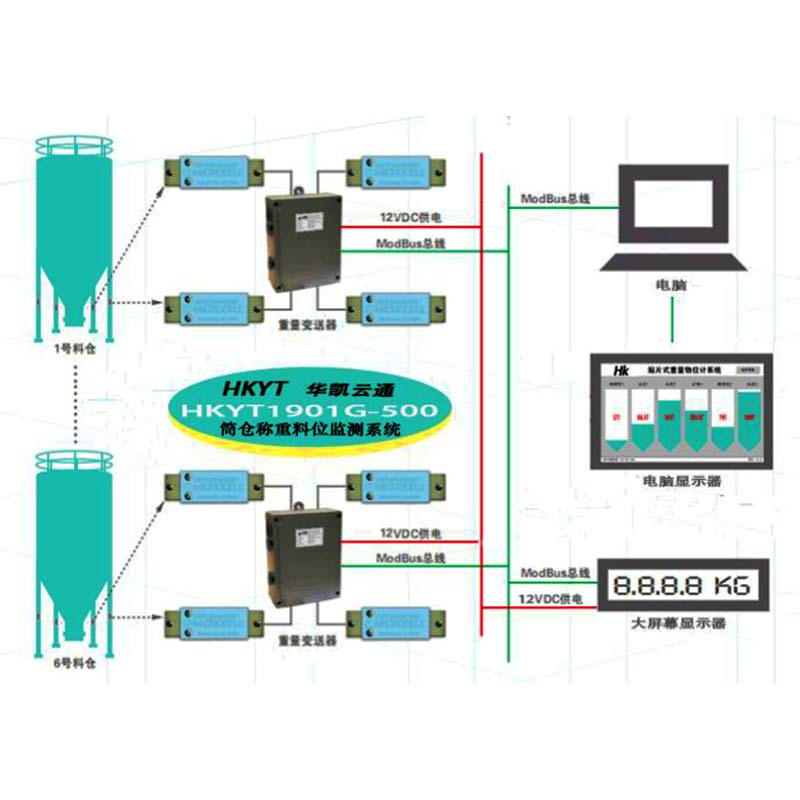

Silo Bulk Material Weighing and Monitoring System

Revolutionize your silo management with our advanced Bolted Cement Silo Bulk Material Weighing System, leveraging cutting-edge German micro-strain sensor technology and IoT solutions for end-to-end digitalized storage management. Unlike traditional level sensors prone to mechanical failures, our system uses multi-point weight monitoring to deliver precise, real-time data on bulk material storage, ensuring safety, efficiency, and operational control. With a minimum precision error of ≤1% (and ≤3% under normal conditions), it eliminates risks of understocking, overfilling, and manual inspection hazards while integrating seamlessly with ERP and industrial software for smart, data-driven decision-making. Designed for easy installation on silo support legs, this system transforms your silo into an intelligent weighing unit, ideal for industries relying on bulk material storage.