- Home

- >

- Products

- >

- Bolted Assembly Steel Silo System

- >

- Bulk Material Tons Packaging System

Bulk Material Tons Packaging System

Product origin :China

CAFU offers customization ton packaging systems for a wide range of bulk material handling, designed to meet the unique needs of a variety of industries.

What is the ton packing system?

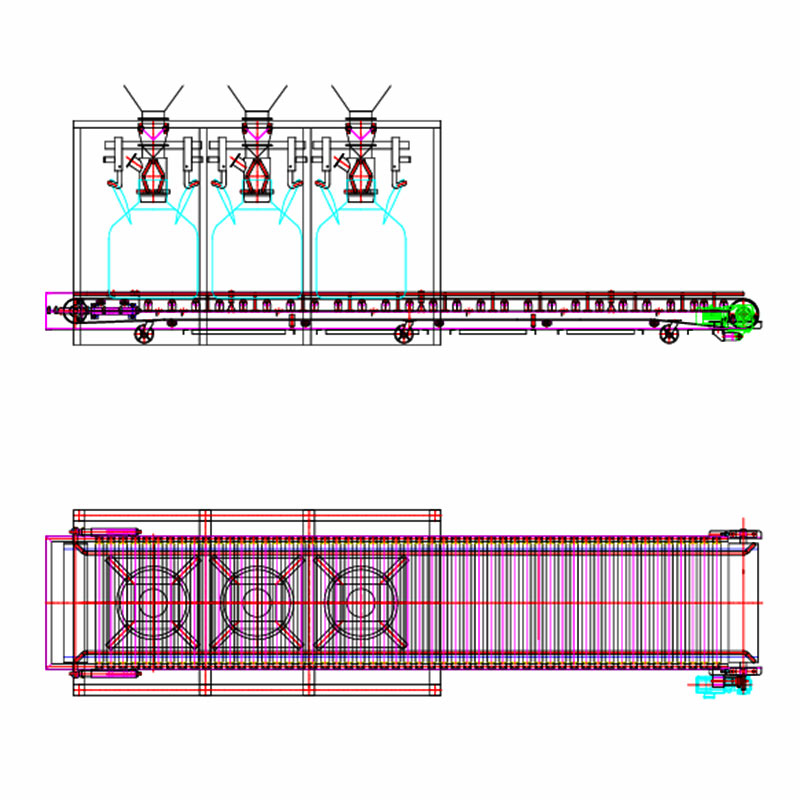

A custom ton packaging system is a comprehensive solution engineered for packaging large - volume (ton - scale) bulk materials. It integrates multiple key components: buffer silos for material storage and flow stabilization, screw gates and pneumatic butterfly valves for precise material control, pneumatic hook - release devices for seamless bag handling, dust collector units for a clean working environment, ton bag weighing conveyors for accurate measurement, and ton bag electrical control systems for automated operation.

These systems are highly customization, catering to diverse material characteristics (such as granular, powdery, or abrasive substances) and industry requirements (including chemicals, minerals, and food ingredients).

Key Components and Their Roles

○ Buffer Silo

The buffer silo acts as a material reservoir. It ensures a continuous and stable material supply to the packaging process, preventing interruptions caused by uneven material flow. This is crucial for maintaining a smooth packaging rhythm, especially in high - volume production lines.

○ Valves and Flow Control Valve

The valves and flow control valve work in tandem to control the material discharge precisely. The Unloading valves offers fine - tuned control for slow and accurate material feeding, while the flow control valve enables rapid on - off operations for large - volume material release. Together, they ensure that the right amount of material is dispensed into the ton bag at the right time.

○ Pneumatic Hook - Release Device

This component simplifies the handling of ton bags. The pneumatic hook - release mechanism allows for quick and secure attachment and detachment of ton bags, reducing manual labor intensity and improving the efficiency of the bag - changing process.

○ Dust Collector

In bulk material packaging, dust generation is inevitable. The dust collector unit effectively captures and removes airborne dust particles, creating a clean and safe working environment. This is not only beneficial for worker health but also helps in complying with environmental regulations, especially in industries with strict air quality standards.

○ Ton Bag Weighing Conveyor

Accurate weighing is the cornerstone of ton bag packaging. The ton bag weighing conveyor integrates weighing technology with conveyor functionality. It precisely measures the material weight as it is loaded into the ton bag, ensuring that each bag meets the specified weight requirements. This eliminates product waste due to overfilling and customer complaints due to under filling.

○ Ton Packaging Electrical Control System

The electrical control system serves as the brain of the entire packaging system. It automates the operation of all components, from material feeding and bag handling to weighing and dust collection. Operators can set parameters, monitor the process in real - time, and receive alerts in case of any deviations, ensuring consistent and efficient packaging operations.

Applications Across Industries

Custom ton packaging systems find applications in a wide range of industries:

● Cement Industry

● Chemical Industry

● Mining and Minerals

● Food and Beverage

● Agriculture

Professional Customized Services

Choose CAFU Machinery to customize a high - reliability ton packaging system for you. Our professional team has rich experience in the design and manufacturing of bulk material packaging equipment. We will tailor - make a solution that perfectly fits your production process according to your material characteristics, output requirements and site conditions.

Now, contact our team right away and submit your specific needs. Let us work together to create an efficient, accurate and stable ton packaging system, helping your enterprise to improve production efficiency and enhance product quality in bulk material handling.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more