- Home >

- Products

-

Apron Feeder

Apron Feeder are mainly used in production lines for quarries, aggregate processing, and large particle recycling applications. Apron Feeder is an important receiving and conveying device for heavy granular bulk materials. Due to the heavy-duty design of the apron feeder, it can withstand instantaneous discharge impact load, and is suitable for feeding large, massive, abrasive and heavy aggregates in humid, viscous or frozen operating environments, and is suitable for various occasions.

-

Versatile LTS Series Apron Feeder

In the realm of industrial material transportation, the LTs series apron feeder stands out as a premium solution for seamlessly moving various lumpy or bulk materials from storage bins to crushers, conveyors, or other machinery—whether in horizontal or inclined setups. Catering to diverse industrial needs, this series is available in light and medium - duty types, making it an ideal choice for industries such as mining, metallurgy, and cement. It truly excels when handling large and sharp materials, ensuring reliable performance even in challenging scenarios.

-

Vertical Bucket Elevator

CAFU Machinery's Bucket Elevator with high-cost performance is a commonly used material conveying equipment, which is widely used in various industries, especially when lifting large granular materials. The Bucket Elevator is mainly divided into five types: TD, TH, TDG, NE and NSE.

-

Z Bucket Conveyor

Application range of Z-type bucket elevator: Chemical industry, refractory material industry, quartz sand industry, sand and gravel industry, metal powder industry, PVC monolithic particles, pet food industry, grain finishing industry, hardware and electrical engineering industry, etc. Material size requirements and production capacity of Z-type bucket elevator: Feeding size ≤3cm; production capacity 1~20m3/h.

-

Dosing System

Dosing system is an advanced technology used in various industries for accurate dosing of liquids or solids. It is widely used in pharmaceutical, food and beverage, water treatment and many other industries where accurate dosing is critical. The system is designed to automate the dosing process, ensuring consistent and efficient production. With programmable settings, real-time monitoring and remote control, this dosing system provides a reliable and convenient solution. Whether it's drug dispensing, flavoring in food production or chemicals in water treatment, dosing system plays a vital role in ensuring the right amount of substance is available at the right time.

-

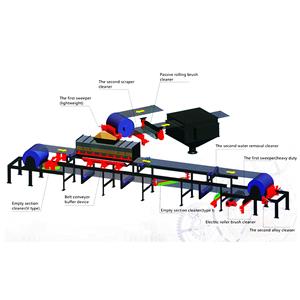

Conveyor Belt Cleaning Solutions

CAFU Machinery, as a professional company specializing in bulk material handling products, supplies high quality belt scraper & conveyor scraper with excellent cost performance.

-

Metal Detector

Conveyor Belt Conveyor Metal Detector Conveyor belt metal side detector is mainly used for metal detection of materials in belt conveying. It is generally installed at the back end of the magnetic separator for double protection.

-

Fu Type Chain Conveyor

Chain conveyor is a new type of equipment for conveying powdery and small granular materials. It can be installed horizontally or within 15° of inclination. It has the advantages of reasonable design, long service life, reliable operation, energy saving and high efficiency, sealing, safety and convenient maintenance. Chain conveyor is widely used in building materials, chemicals, thermal power, food processing, mining, metallurgy, ports and other industries.

-

Permanent Magnet for Belt Conveyor

RCDB Dry Electromagnetic Separator and RCDD Electromagnetic Self-Unloading Separator Scope of application: It is used to remove iron from any material in front of the crusher and on the conveyor belt, and can be applied to various harsh environmental conditions. Electromagnetic iron remover plays a key role in protecting terminal equipment from hard steel impurities in conveyed materials.