- Home

- >

- Products

- >

- Bulk Material Conveying Equipment

- >

- Conveyor Belt Cleaning Solutions

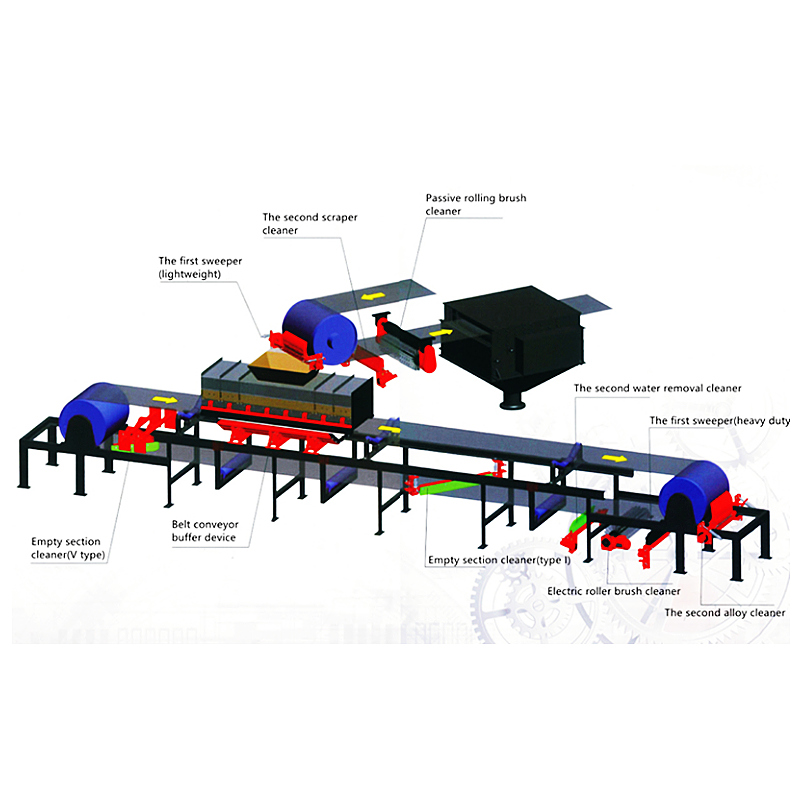

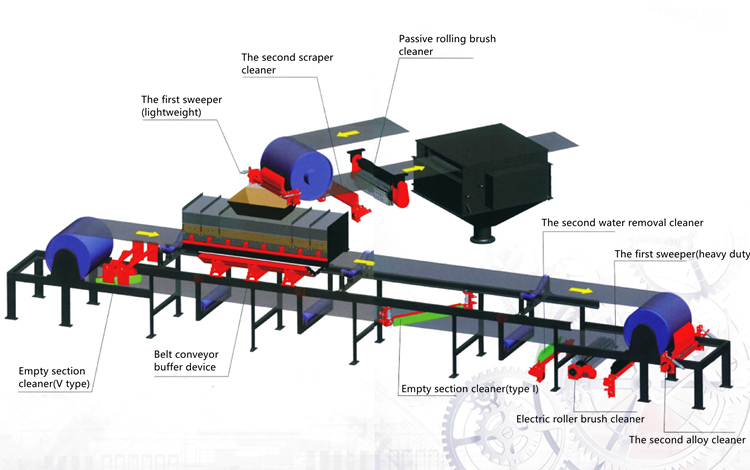

Conveyor Belt Cleaning Solutions

Brand :BK

Product origin :China

CAFU Machinery, as a professional company specializing in bulk material handling products, supplies high quality belt scraper & conveyor scraper with excellent cost performance.

Conveyor Belt Cleaning Solutions

● Belt scraper & Conveyor scraper

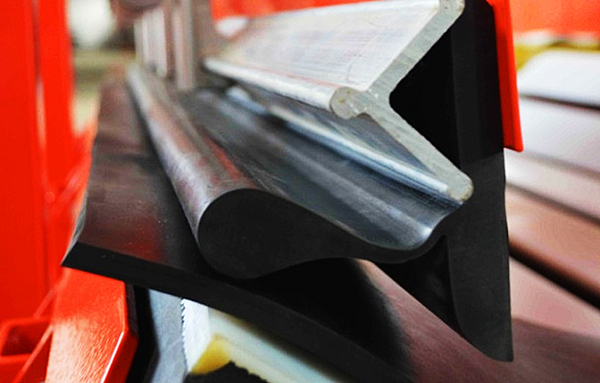

1. Conveyor belt cleaning-first step

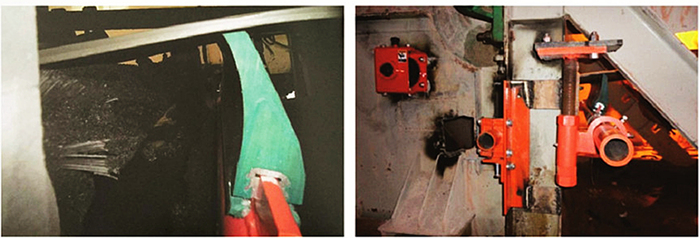

◆Scene picture:

It is suitable for material cleaning of high-speed belts on conveyor unloading rollers.The conveyor belt cleaner is divided into light type and heavy type.

Features:

1. The cleaning blade is made of special polyurethane, which is flame retardant and antistatic, high wear resistance, high elasticity, strong acid resistance, low friction coefficient, will not cause damage to the conveyor belt, and has a long service life.

2. Compared with the heavy-duty cleaner, the blade of the super-heavy cleaner has a larger increase in height and thickness.

3. The blade compensation can be adjusted according to the degree of blade wear.

4. The blade material is polyether material, which is 50% higher in wear resistance than ordinary polyurethane material, and the molecular weight is more than 9 million.

5. The buffer system is divided into primary buffering and secondary buffering, which improves the buffering effect of the frame and thus prolongs the service life of the cleaner.

Specification model table:

Product number | Belt width(mm) | Blade width(mm) | Length of telescopic rod(mm) |

BK - YNZQC -B650 | 650 | 610 | 650 |

BK - YNZQC -B800 | 800 | 762 | 650 |

BK - YNZQC -B1000 | 1000 | 915 | 650 |

BK - YNZQC -B1200 | 1200 | 1067 | 850 |

BK - YNZQC -B1400 | 1400 | 1220 | 850 |

BK - YNZQC -B1600 | 1600 | 1372 | 850 |

BK - YNZQC -B1800 | 1800 | 1524 | 850 |

BK - YNZQC -B2000 | 2000 | 1676 | 850 |

◆Information that users need to provide when ordering products:

1. Belt width

2. material characteristics

3. working environment

4. belt speed

5. belt joint mode

6. head wheel diameter

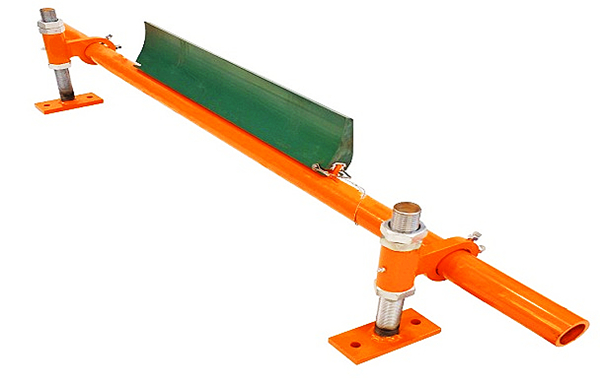

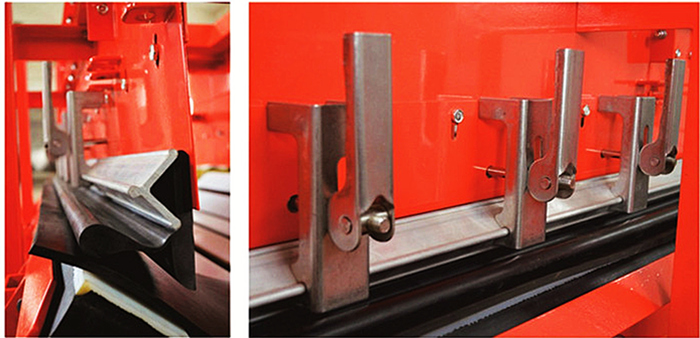

2. Conveyor belt cleaning-scraper cleaner

◆Scene picture:

◆Product Description:

BK-ENQC series polyurethane cleaners are equipped with wear-resistant blades that are easy to replace, have the advantages of quickly removing materials on the belt working surface, and high-energy spring shock-proof design. The scraper conveyor belt cleaner is used in conjunction with the first conveyor belt cleaner, and the cleaning effect is better.

Structure function and characteristics:

The unique tensioning device combined with high-performance springs can make the blade adhere to the belt tightly when the belt is constantly shaking, maintain a stable tension, and reduce the fatigue damage to the blade base due to shaking , Improve the service life of the blade.

Easy to use and easy to maintain. Adjust the tension of the knife edge without disassembling the cleaner, just adjust the screw on the tensioner. The cleaner has obvious cleaning results, long-lasting durability, and is highly praised by users.

Application range:

Material conveying belt systems in coal mines, cement plants, steel plants, power plants and other factories.

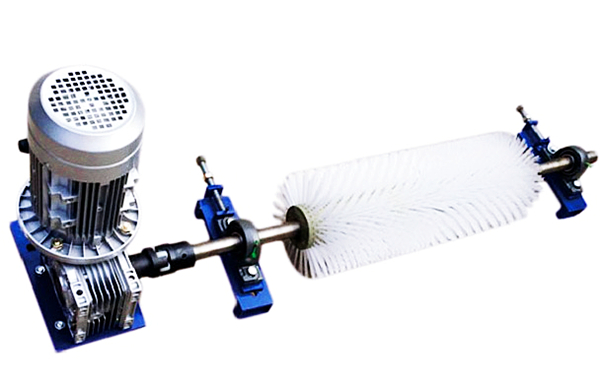

3. Passive rolling brush cleaner

◆Scene picture:

◆Structure function and characteristics:

BK-NLW series unpowered rotary cleaner is a new product designed innovatively based on the defects of the cleaners currently in common use.

Its characteristics are as follows:

1. Optimized design, easy to install, easy to adjust, convenient and practical;

2. No need for power supply and control devices, only increase the conveyor power by 1-2%, saving materials and energy;

3. The cleaning point is elastically contacted, the method is reasonable, and the effect is excellent;

4. There is no wear to the conveyor belt, and no scratches, which effectively prolongs the service life of the belt;

5. The cleaning process does not interfere with the normal operation of the conveyor;

6. Safe and reliable, low failure rate, long service life, low maintenance cost;

7. The bristles can be made of high-elasticity and wear-resistant nylon wire, or made of high-quality materials such as anti-static high-elasticity nylon wire and wear-resistant rubber, which are suitable for users in various industries.

◆Specification model table:

Product number | Belt width(mm) | Length of brush roller(mm) | Roller length(mm) | Installation location |

BK - NLW-B650 | 650 | 790 | 750 | Return belt |

BK - NLW-B800 | 800 | 950 | 900 | Return belt |

BK - NLW-B1000 | 1000 | 1150 | 1100 | Return belt |

BK - NLW-B1200 | 1200 | 1350 | 1300 | Return belt |

BK - NLW-B1400 | 1400 | 1550 | 1500 | Return belt |

BK - NLW-B1600 | 1600 | 1750 | 1700 | Return belt |

BK - NLW-B1800 | 1800 | 1950 | 1900 | Return belt |

BK - NLW-B2000 | 2000 | 2150 | 2100 | Return belt |

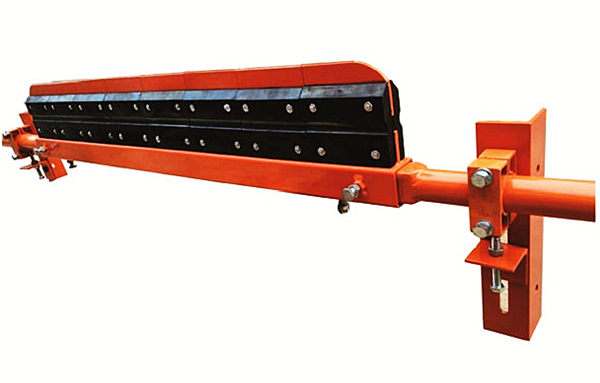

4. V-shaped empty section cleaner

◆Scene picture:

◆Specification model table:

Product number | Belt width(mm) | Blade width(mm) | Installation location |

BK - KQC -B650 | 650 | 1400 | Non-working surface of return belt |

BK - kQC -B800 | 800 | 1700 | |

BK - kQC -B1000 | 1000 | 2100 | |

BK - kQC -B1200 | 1200 | 2500 | |

BK - kQC -B1400 | 1400 | 2900 | |

BK - kQC -B1600 | 1600 | 3300 | |

BK - kQC -B1800 | 1800 | 3700 | |

BK - kQC -B2000 | 2000 | 4100 |

5. Belt conveyor buffer cradle

◆Scene picture:

Non-standard products, customized size

6. I-type empty section cleaner

◆Scene picture:

The I-type empty section cleaner is installed at the tail of the belt conveyor, on the flat surface of the return belt at a distance of 1.5m-3m from the tail wheel. Under the action of the tensioner, the blade is attached to the non-working surface of the belt, and the material spilled on the belt is cleaned up to avoid belt damage and deviation caused by the material entering the tail wheel.

The two-way empty section cleaner is suitable for two-way running belt conveyors. The cleaner is equipped with an HTEI type tensioner and is installed on the flat surface above the non-loading surface of the two-way return belt. Under the action of the tensioner, the blade is attached to the surface of the return belt to clean the material on the belt, which is beneficial to the normal operation of the belt and the tail wheel, and prevents the belt from slipping. It is used with K2# tensioner.

◆Specification model table:

Product number | Belt width(mm) | Blade width(mm) | Installation location |

BK - IQC -B650 | 650 | 750 | Non-working surface of return belt |

BK - IQC -B800 | 800 | 900 | |

BK - IQC -B1000 | 1000 | 1100 | |

BK - IQC -B1200 | 1200 | 1300 | |

BK - IQC -B1400 | 1400 | 1500 | |

BK - IQC -B1600 | 1600 | 1700 | |

BK - IQC -B1800 | 1800 | 1900 | |

BK - IQC -B2000 | 2000 | 2100 |

7. Conveyor Belt Cleaner-Dewatering Cleaner

◆Scene picture:

Conveyor Belt Cleaner-Dewatering Cleaner is currently the most reliable secondary flexible cleaner. It can not only remove adhesions, but also effectively remove moisture from the belt. If a spray device is installed, it can function as a cleaning box and can clean contaminated belts.

Features:

1. Use a rubber brush to clean the belt with the polyurethane secondary blade to effectively remove dirt and moisture.

2. Optional double-sided blades/dual hosts are installed on a single bracket to achieve the maximum cleaning efficiency with the smallest hardware.

3. There is a nozzle attached to the cleaner, which sprays water onto the belt, which can be used to reduce dust and improve the cleaning efficiency.

◆Specification model table:

Product number | Belt width(mm) | Blade width(mm) | Total length of the rack(mm) |

BK - NCS -B650 | 650 | 650 | 1390 |

BK - NCS -B800 | 800 | 800 | 1540 |

BK - NCS -B1000 | 1000 | 1000 | 1840 |

BK - NCS -B1200 | 1200 | 1200 | 1990 |

BK - NCS -B1400 | 1400 | 1400 | 2140 |

BK - NCS -B1600 | 1600 | 1600 | 2440 |

BK - NCS -B1800 | 1800 | 1800 | 2590 |

BK - NCS -B2000 | 2000 | 2000 | 2890 |

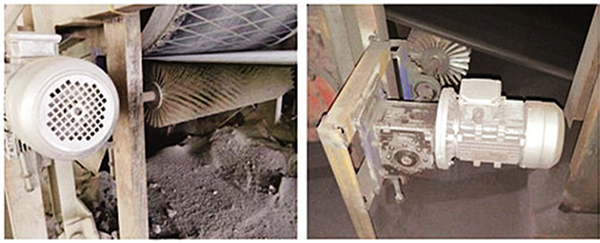

8. Electric roller brush cleaner

◆Scene picture:

The BK series electric roller cleaner is a newly developed new cleaner. The nylon brush roller is easy to replace, the brush wire is wear-resistant, highly elastic, and high temperature resistant. The material is 1010 nylon wire. It has the advantages of quickly removing materials on the working surface of the belt, without damaging the belt, long service life, and easy installation. The BK series electric roller brush cleaner works better with the polyurethane cleaner.

◆Features:

1. Optimized design, easy to install, easy to adjust, simple and practical.

2. The cleaning method is reasonable and the effect is excellent.

3. There is no wear to the conveyor belt, and no scratches, which effectively prolongs the service life of the belt.

4. Safe and reliable, low failure rate, long service life and low maintenance cost.

5. The bristles can be made of high-elastic nylon wire, anti-static high-elastic nylon wire, wear-resistant rubber and other high-quality materials. It is widely used in various material conveying belt systems such as coal mines, cement plants, steel plants, and power plants.

Specification model table:

Product number | Belt width(mm) | Motor Power(mm) | Length of brush roller(mm) | Installation location |

BK - LXQ-B650 | 650 | 1.1 | 1300 | Return belt |

BK - LXQ-B800 | 800 | 1.1/1.5 | 1450 | Return belt |

BK - LXQ-B1000 | 1000 | 1.5 | 1650 | Return belt |

BK - LXQ-B1200 | 1200 | 2.2 | 1850 | Return belt |

BK - LXQ-B1400 | 1400 | 2.2 | 2050 | Return belt |

BK - LXQ-B1600 | 1600 | 2.2/3 | 2250 | Return belt |

BK - LXQ-B1800 | 1800 | 3 | 2450 | Return belt |

BK - LXQ-B2000 | 2000 | 3/4 | 2650 | Return belt |

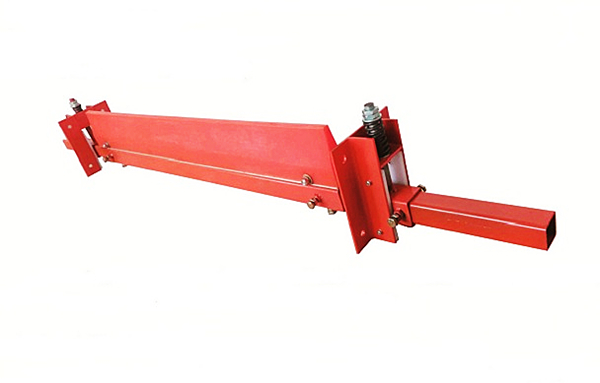

9. Conveyor Belt Cleaner-Alloy Cleaner

◆Scene picture:

◆Features:

1. The blade is made of special polyurethane material or natural rubber and tungsten carbide composite nano material, and the cleaning is particularly clean.

2. Not suitable for conveyor belts with metal buckles.

3. According to the blade wear, the blade compensation can be adjusted to keep the blade close to the conveyor belt.

◆Specification model table:

Product number | Belt width(mm) | Blade width(mm) | Length of telescopic rod(mm) |

BK - HJQC -B650 | 650 | 650 | 650 |

BK - HJQC -B800 | 800 | 800 | 650 |

BK - HJQC -B1000 | 1000 | 1000 | 650 |

BK - HJQC -B1200 | 1200 | 1200 | 850 |

BK - HJQC -B1400 | 1400 | 1400 | 850 |

BK - HJQC -B1600 | 1600 | 1600 | 850 |

BK - HJQC -B1800 | 1800 | 1800 | 850 |

BK - HJQC -B2000 | 2000 | 2000 | 850 |

10. JWHSR

◆Scene picture:

Upgrading your belt scraper system according to your bulk material characteristics is our specialty. We offer a comprehensive and cost-effective range of conveyor scraper products to ensure the reliability of your belt conveyor system.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more