- Home >

- Products

-

Diamond Router Bit for Stone Edge Trimming

The Diamond Router Bit for Stone Edge Trimming is a specialized stone - working tool for handheld router bit machines. In the field of stone processing, it is widely used for cutting and grinding the edges of stone countertop panels. According to the processing profile requirements, there are more than ten types of profiles such as a, b, e, f, h. This diamond router bit can adapt to stone processing processes from rough machining to fine grinding, and is one of the most widely used diamond tools for stone countertop processing.

-

Diamond Profile Wheel for Stone Cutting

Diamond Profile Wheel is an abrasive tool for processing hard and brittle materials, composed of a metal matrix, diamond abrasives, and a bonding agent. Boasting high hardness, strong wear resistance, high processing precision and efficiency, as well as good heat dissipation, it is widely used in cutting and edging of stone, glass, ceramics, etc. By means of high-speed rotation of abrasives for grinding or cutting materials, it enhances processing quality and efficiency.

-

Sintered Diamond Milling Wheels for Bridge Saws and CNC

In the field of stone processing, achieving precise thickness control and excellent surface finishing is crucial for meeting the stringent requirements of construction and decoration projects. The Sintered Diamond Calibrating Wheel emerges as a solution for precise rough - blank processing of stone, designed to deliver outstanding performance in stone thickness adjustment.

-

Sintered Diamond CNC Stubbing Wheel for Stone Slab Calibration

CAFU's high-quality Sintered Diamond CNC Stubbing Wheel is one of the preferred diamond tools for stone processing. Our Stubbing Wheels are meticulously designed to deliver exceptional performance in processing marble, granite, engineered stone, and more. Leveraging high-grade synthetic diamonds and top-quality raw materials, we provide customized solutions to create the most durable, safe, and reliable diamond tools for your specific needs.

-

Air Wet Polisher for Stone

This professional-grade 4-inch air-powered wet stone polisher is built for surface treatment of hard materials such as granite, marble, concrete, and ceramic tiles. It has a lightweight aluminum alloy body and an ergonomic grip, ensuring comfort even during long - hour work. The rear exhaust system optimizes airflow direction, lowering noise to below 75dB and preventing dust splashing, creating a safe workspace. With 5/8"-11, M14, and M16 connection options, it easily pairs with various grinding discs on the market, bringing great convenience for different polishing tasks.

-

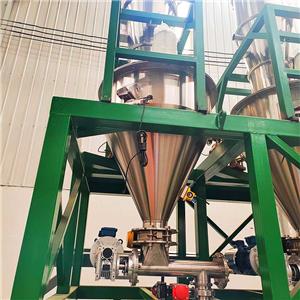

Loss In Weight Feeder for Bulk Materials

In industrial operations that handle bulk materials, accurate weighing is the cornerstone of ensuring efficiency, quality control, and compliance. CAFU Machinery can customize high-precision weighing systems for a wide range of bulk materials, including loss in weight feeder, loss in weight feeder system, and more.

-

Power Plant Pipe Conveyor Belt

In power generation facilities, the reliable transportation of bulk materials like coal, wood chips, and biomass is critical to ensure uninterrupted energy production. The pipe conveyor belt (also known as tubular belt conveyor) has emerged as an optimal solution, combining environmental protection, high efficiency, and adaptability to complex plant layouts. Designed with a closed cylindrical belt structure, this system addresses the challenges of dust emission, material spillage, and space constraints, making it ideal for power plant applications.

-

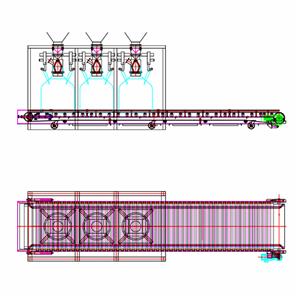

Bulk Material Tons Packaging System

CAFU offers customization ton packaging systems for a wide range of bulk material handling, designed to meet the unique needs of a variety of industries.

-

Small Bag Feeding Station

In industries such as chemical, food, pharmaceutical, and battery manufacturing, efficient and clean material handling during the feeding process is crucial. The small bag feeding station emerges as a key equipment to meet these demands, addressing dust pollution issues and ensuring smooth production workflows.