- Home

- >

- Products

- >

- Powder Pneumatic Conveying System

- >

- Vacuum Feeder for Bulk Materials Handling

Vacuum Feeder for Bulk Materials Handling

Product origin :China

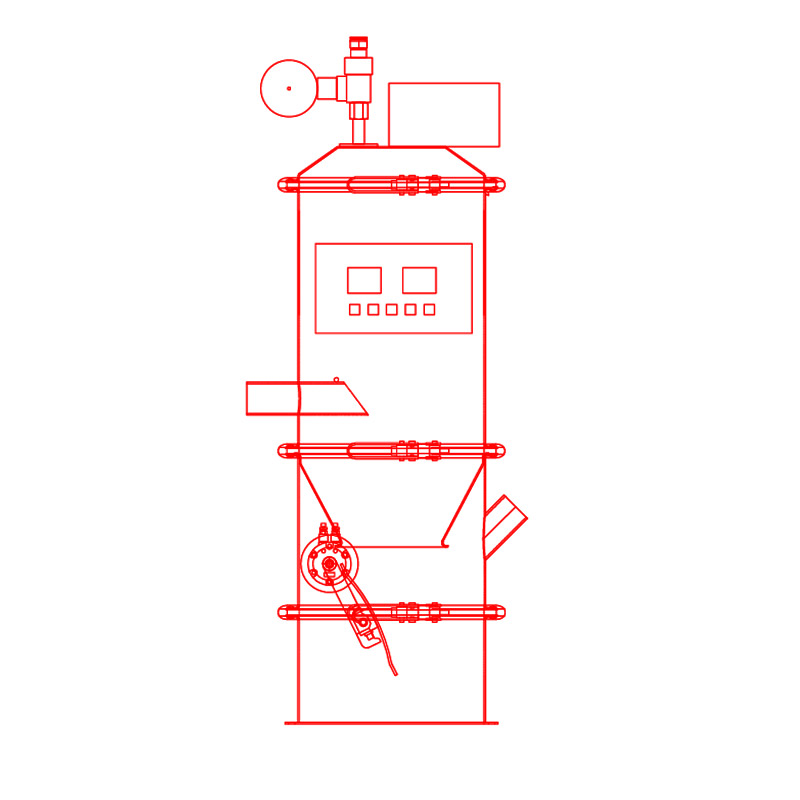

Vacuum feeders for bulk material handling are highly efficient pneumatic conveying devices for small flows of powdered or granular materials over short distances. Whether in the pharmaceutical, food processing or chemical manufacturing sectors, this equipment is indispensable for companies seeking to optimize their production workflow.

Vacuum Feeder Machine: Efficient Bulk Material Handling Solution

What is a Vacuum Feeder Machine?

A vacuum feeder machine, also known as a pneumatic vacuum conveyor, is a cutting - edge device that leverages compressed air to create a high - vacuum environment via a vacuum generator. This innovative mechanism enables the seamless transport of various materials without the need for a traditional mechanical vacuum pump.

Key Advantages of Vacuum Feeder Machines

1. Simplified Design and Compact Size

The vacuum feeder boasts a simple structure and small footprint. This means it can be easily integrated into existing production lines, even in facilities with limited space. Its compact nature also simplifies installation and relocation processes, providing flexibility for businesses as their operational needs evolve.

2. Low - Maintenance and User - Friendly

One of the most appealing aspects is its maintenance - free operation. Unlike some complex machinery that requires frequent part replacements and intricate upkeep, the vacuum feeder is designed for long - term, hassle - free use. Additionally, it features convenient control systems, allowing operators to manage material transportation with ease, reducing the learning curve and minimizing human error.

3. Quiet Operation and Safety Features

With low noise production, the vacuum feeder creates a more pleasant working environment. Moreover, it incorporates features like static electricity elimination, which is crucial for handling materials that are sensitive to electrostatic discharge.

4. Ensuring Uniform Material Composition

The high vacuum generated by the vacuum generator plays a vital role in material transportation. It prevents the material from stratifying during transit, thus ensuring the uniformity of the mixture's composition. This is particularly important for processes where consistent material quality is paramount, such as in tablet pressing, capsule filling, dry granulation, packaging, crushing, and vibrating screen operations.

Technical Specifications of Vacuum Feeder Machines

The following table outlines the key technical parameters of different models of vacuum feeder machines. These models are designed to cater to varying production scales and material handling requirements:

Model | Conveying Capacity | Vacuum Silo Volume | Air Pressure Range | Compressed Air Consumption |

VFM - 100 | 50 - 300Kg/h | 1.1L | 0.4 - 0.6Mpa | 180NL/min |

VFM - 200 | 100 - 700kg/h | 6L | 0.4 - 0.6Mpa | 360NL/min |

VFM - 300 | 300 - 1500kg/h | 12L | 0.4 - 0.6Mpa | 720NL/min |

VFM - 400 | 600 - 3000Kg/h | 42L | 0.4 - 0.6Mpa | 1440NL/min |

Please note: The above specifications and parameters will vary with different materials.

These models showcase the versatility of vacuum feeder machines, with varying conveying capacities to suit small - scale laboratory operations as well as large - scale industrial production lines. The consistent air pressure range across models ensures reliable performance, while the compressed air consumption is optimized to balance efficiency and cost - effectiveness.

Applications Across Industries

The vacuum feeder machine finds extensive application across a multitude of industries:

1. Pharmaceuticals: Ideal for feeding equipment in tablet presses and capsule filling machines, where precision and material integrity are non - negotiable.

2. Food Processing: Used in processes like dry granulation and packaging, ensuring that food materials are handled in a hygienic and efficient manner.

3. Chemical Manufacturing: Suited for transporting chemicals in crushing and vibrating screen operations, where the prevention of material stratification is crucial for product quality.

4. New Energy Industry: Handling of negative battery materials.

Why Choose a Vacuum Feeder Machine?

In a competitive industrial landscape, efficiency, cost - effectiveness, and product quality are key differentiators. The vacuum feeder machine delivers on all these fronts. Its ability to handle a wide range of materials, combined with its low - maintenance design and compliance with industry standards, makes it a valuable asset for any business looking to enhance their material handling processes.

Whether you are a small - scale manufacturer seeking to improve workflow efficiency or a large enterprise aiming to maintain stringent quality control, the vacuum feeder machine offers a tailored solution.

To explore how a vacuum feeder machine can be customized to meet your specific bulk material handling needs, reach out to the CAFU service team today. Let us help you unlock the full potential of your production line with this innovative material handling solution.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more