- Home

- >

- Products

- >

- Stone Processing Equipment and Diamond Tools

- >

- Diamond Profile Wheel for Stone Cutting

Diamond Profile Wheel for Stone Cutting

Product origin :China

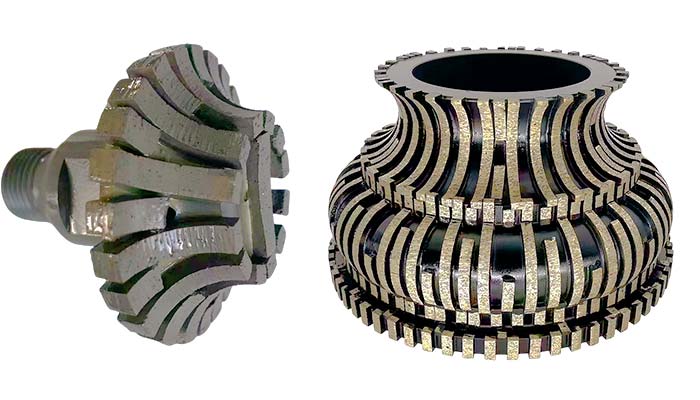

Diamond Profile Wheel is an abrasive tool for processing hard and brittle materials, composed of a metal matrix, diamond abrasives, and a bonding agent. Boasting high hardness, strong wear resistance, high processing precision and efficiency, as well as good heat dissipation, it is widely used in cutting and edging of stone, glass, ceramics, etc. By means of high-speed rotation of abrasives for grinding or cutting materials, it enhances processing quality and efficiency.

Diamond Profile Wheel for Stone Cutting: Precision, Performance, and Versatility

Unveiling the Diamond Profile Wheel

A diamond profile wheel is a specialized grinding tool engineered for processing hard and brittle materials like stone, glass, and ceramics. Its construction comprises three core components:

● Metal Matrix: Typically crafted from aluminum or steel, it provides structural stability and supports the diamond abrasive layer during high-speed rotation.

● Diamond Abrasives: The heart of the wheel, these ultra-hard particles enable precise material removal, leveraging diamond's natural hardness to ensure long-lasting sharpness.

● Bonding Agent: Resins, metals, or ceramics bind the diamond abrasives to the matrix, influencing the wheel's performance, lifespan, and suitability for specific tasks.

Key Features for Superior Stone Cutting

Diamond profile wheels deliver a suite of benefits that elevate stone processing:

● High Hardness & Wear Resistance: Diamond's unmatched hardness ensures the wheel maintains its cutting edge, reducing tool replacement frequency and boosting productivity.

● Precision Machining: Capable of achieving tight tolerances, these wheels produce intricate profiles (e.g., bullnose, ogee) and smooth finishes.

● Efficient Material Removal: The combination of high-quality diamond abrasives and an optimized metal matrix formula design delivers unparalleled cutting performance, enabling rapid cutting and grinding to minimize processing time for large-scale projects.

● Thermal Stability: Effective heat dissipation can prevent abnormal wear of profile wheels, optimize the processing performance of diamond tools, and extend the wheel lifespan.

Diverse Applications Across Industries

Diamond profile wheels excel in multiple stone working scenarios:

● Stone Fabrication: Ideal for cutting, edging, and profiling granite, marble, quartz, and engineered stones. They create decorative lines (e.g., door casings, skirting boards) and precision-cut components for countertops, tiles, and monuments.

● Glass & Ceramic Processing: Used for cutting, beveling, and finishing glass panels (architectural, furniture) and ceramic tiles, ensuring clean edges and accurate dimensions.

● Specialized Materials: Extend to processing hard alloys, semiconductors, and gemstones, serving aerospace, electronics, and jewelry sectors with precision.

Technical Specifications: V-Type & B-Type Profile Wheels

The following table outlines the commonly used standard specifications for V-Type and B-Type diamond profile wheels compatible with edge cutting machines and bridge saws. For other sizes or various diamond profile wheels used in CNC machines, customized sizes and configurations are available to meet unique project needs.

Item No. | Type | Outer Diameter (Inch/mm) | Stone Thickness (mm) | Thread Size (mm) |

V10-12(14) | Segmented | 12/14 / Φ300/Φ350 | 10 | 50/60 |

V20-12(14) | Segmented | 12/14 / Φ300/Φ350 | 20 | 50/60 |

V30-12(14) | Segmented | 12/14 / Φ300/Φ350 | 30 | 50/60 |

V40-12(14) | Segmented | 12/14 / Φ300/Φ350 | 40 | 50/60 |

B10-12(14) | Segmented | 12/14 / Φ300/Φ350 | 10 | 50/60 |

B15-12(14) | Segmented | 12/14 / Φ300/Φ350 | 15 | 50/60 |

B20-12(14) | Segmented | 12/14 / Φ300/Φ350 | 20 | 50/60 |

B25-12(14) | Segmented | 12/14 / Φ300/Φ350 | 25 | 50/60 |

B30-12(14) | Segmented | 12/14 / Φ300/Φ350 | 30 | 50/60 |

Why Choose CAFU's Diamond Profile Wheels?

● Premium Materials: High-grade diamonds and durable bonding agents ensure maximum wear resistance and cutting efficiency.

● Precision Engineering: G2.5-level dynamic balance minimizes vibration, enhancing cutting accuracy and machine longevity.

● Customization Flexibility: Tailored sizes, shapes, and bond types to match specific stone types and CNC machine requirements.

● End-to-End Solutions: From rough shaping to fine polishing, CAFU offers a complete range of wheels for every stage of stone processing.

Diamond profile wheels are one of the most commonly used cutting tools in stone cutting, combining precision, durability, and versatility to meet the needs of various applications. Whether shaping granite countertops or finishing delicate quartz surfaces, these tools deliver consistent, high-quality results. For professionals seeking to optimize efficiency and elevate craftsmanship, choosing CAFU's diamond profile wheels is an excellent choice.

Ready to enhance your stone processing efficiency? Explore CAFU's diamond profile wheel range and experience the difference in precision and productivity.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more