- Home

- >

- Products

- >

- Powder Pneumatic Conveying System

- >

- Loss In Weight Feeder for Bulk Materials

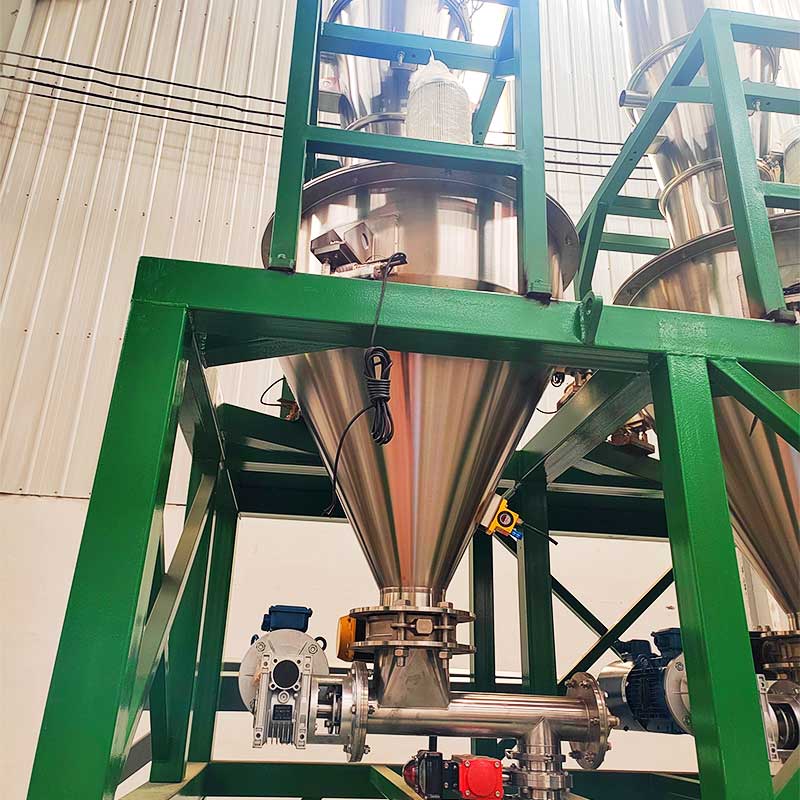

Loss In Weight Feeder for Bulk Materials

Product origin :China

In industrial operations that handle bulk materials, accurate weighing is the cornerstone of ensuring efficiency, quality control, and compliance. CAFU Machinery can customize high-precision weighing systems for a wide range of bulk materials, including loss in weight feeder, loss in weight feeder system, and more.

The loss in weight feeder and loss in weight feeder system is a vital component in the quality control process for bulk material handling. It is a industrial metering device that realizes continuous quantitative feeding by measuring the rate of material weight loss. Its core principle is to use the "dynamic weight loss" principle to calculate the material flow rate in real time and control the feeding speed. It is suitable for the precise metering of bulk materials such as powders, granules and powders, and is indispensable especially in scenarios requiring high-precision batching.

Key Features

The metering accuracy can reach ±0.3%~±1%, far exceeding that of ordinary belt scales (±2%~±5%), making it particularly suitable for scenarios requiring high batching precision (such as the proportioning of lithium battery electrode materials).

2. Material Compatibility: Compatible with a wide variety of bulk materials, from fine powders to granular substances. Its design takes into account the different flow characteristics of these materials to ensure consistent and accurate weighing.

Weigh Hopper for Bulk Materials

○ Material: SUS304 or 316L

○ Volume: 300L or customized volume

○ Feed inlet: Customized according to upstream conveying equipment

Weighing Module

1. The weighing module adopts three-point support design, which provides stability and uniform load distribution, making the overall measurement accuracy reach 0.3%.

2. Load cell: Toledo explosion-proof weighing module.

Unloading device

The quantitative screw with equipped with variable frequency motor and reducer, which can be adjusted to control the flow rate of the bulk material according to the production requirements.

Typical Application Fields

● Chemical Industry: Batching and metering of PVC resins, coating pigments;

● Food and Pharmaceutical Industry: Precise feeding of raw materials for milk powder and tablets (e.g., proportioning of capsule fillers);

● New Energy Field: Weighing and mixing of lithium battery positive and negative electrode materials (e.g., lithium iron phosphate, ternary materials);

● Building Materials Industry: Quantitative feeding of concrete additives, gypsum powder.

For more information on the loss in weight feeder and loss in weight feeder system for your bulk materials, please feel free to contact our service team.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more