- Home

- >

- News

- >

- Industry news

- >

- enclosed belt conveyor

enclosed belt conveyor

Air Cushion Belt Conveyor

The enclosed belt conveyor is belt conveyors for bulk materials with obvious advantages of environmental protection and energy saving in conveyor belt system.

As an excellent representative of bulk material conveyor, air cushion belt conveyor has obvious advantages in bulk material conveying system and is widely used.

In the bulk material conveying equipment, the air cushion belt conveyor is a belt conveyor that uses a thin air film to support the conveyor belt and the materials above it, also known as "air cushion conveyor". It replaces the idler of the ordinary idler belt conveyor with a perforated air chamber. When the air source provides air with a certain pressure and flow into the air chamber, the air in the air chamber escapes through the small holes on the pan groove. A layer of air film is formed between the conveyor belt and the disc groove to support the conveyor belt and the materials on it.

Air-cushion belt conveyors are mostly the same as ordinary belt conveyors, and are also composed of rollers, conveyor belts, driving devices, tensioning devices and other components, but there is no upper idler of ordinary conveyors in the middle section of the conveyor ( Some air cushion conveyors do not use lower idlers), but add components such as blowers and air chambers.

The air-cushion belt conveyor has the advantages of stable and reliable operation, large conveying capacity, long conveying distance, easy starting of the load, the conveyor belt is not easy to deviate and wear, has a long service life, good sealing performance, and no dust during operation.

The working principle of the air cushion belt conveyor: a conveyor belt is surrounded between the driving roller and the tail roller of the air cushion belt conveyor, and the air cushion of the conveyor belt support device supports the conveyor belt and the materials on it.

When the motor rotates the driving drum through the deceleration device, the conveyor belt moves at a certain speed under the driving of the friction force between the drum and the conveyor belt.

The material falls on the moving conveyor belt from the feeding hopper and reaches the discharge port of the head for discharge.

The bandwidth range of the air cushion belt conveyor is 300~2400mm, and the belt speed range is 0.25~6.3m/s.

At present, the maximum conveying capacity of air cushion conveyors that can be manufactured in China can reach 4500t/h.

It has been widely used in coal, electric power, metallurgy, chemical industry, machinery, grain, light industry, port and building materials and other industries.

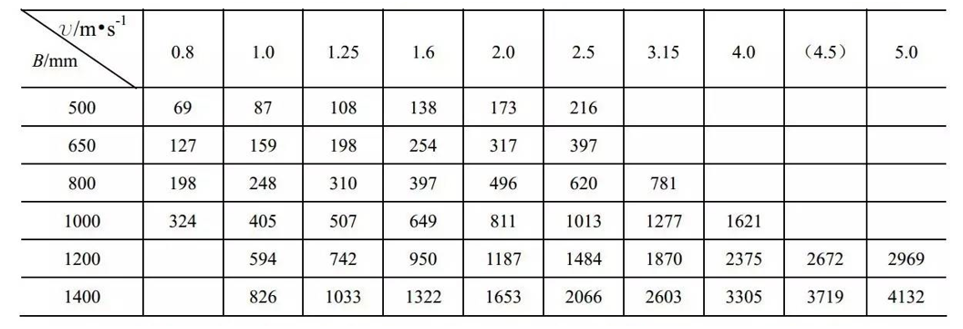

Fig. 1 The relationship between the conveying capacity of the air cushion conveyor

Matching relationship between belt speed v, bandwidth B and volume delivery volume Iv (m³/h)

Note: The Iv value of the conveying capacity is calculated according to the horizontal conveying, the material bulk density is 1000kg/m³, the dynamic accumulation angle θ is 20°, and the air chamber disc groove angle λ is 35°.

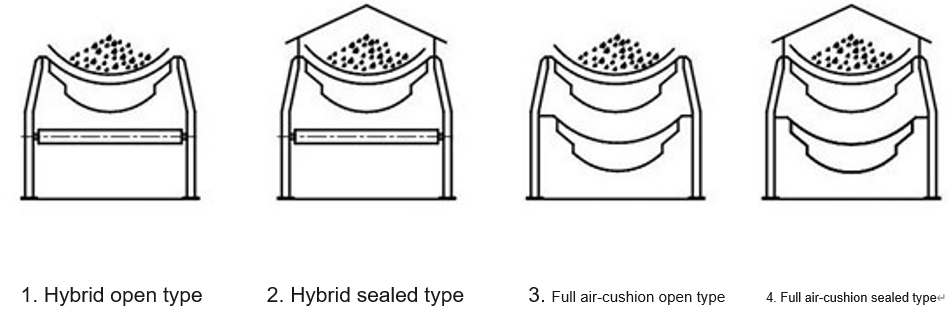

Air cushion belt conveyors can be divided into four types according to whether the upper and lower branch conveyor belts are supported by air cushions and whether a rain cover is added to the air chamber and sealed.

(1) Mixed open type: only the upper branch conveyor belt is supported by air cushion, the lower branch is still supported by rollers, and the air chamber is not equipped with a rain cover;

(2) Hybrid sealed type: A rain cover is added to the air chamber of the hybrid open type and sealed;

(3) Full air-cushion open type: the upper and lower branch conveyor belts are supported by air cushions, and no rain cover is added to the air chamber;

(4) Full air-cushion sealed type: The air chamber of the full air-cushion open type is equipped with a rain cover and sealed.

Figure 2 Four structural types of air cushion conveyor

Compared with ordinary roller belt conveyors, air cushion belt conveyors have the following main advantages:

(1) Less energy consumption: Change the rolling friction to fluid friction, greatly reducing the traction and running resistance, and the more significant the energy saving effect;

(2) Light weight: the air box adopts a box-shaped section, the number of idlers is small (only a few sets of transition idlers are set at each end of the conveyor), the number of layers and thickness of the tape is less, and the self-weight is lighter;

(3) Long service life: Realize full-line protective sealing, low tape tension, less friction, no deviation, no tearing of the tape, and the air cushion has a cooling effect on the tape, so the service life of the equipment is longer than that of the idler conveyor;

(4) Low maintenance costs: fewer rotating parts, fewer accident points, strong reliability, and small wear and tear, greatly reducing maintenance workload and maintenance costs;

(5) The conveying is stable and the environmental protection is good: the operation is very stable, no turbulence, no material scattering, no deviation, and no dust;

(6) The starting power is low, and it can be started directly with full load: after a stable air cushion layer is formed, the starting power of the drive motor is slightly different from the operating power. When the whole line is fully loaded, it can be started directly without auxiliary measures.

The main disadvantages of air cushion belt conveyors are:

(1) It cannot bear the impact load, otherwise the air cushion will be damaged, so the buffer idler is still needed when loading;

(2) Due to the difficulty in the manufacture of the air chamber, the conveyor is not easy to realize the turning of the plane and space, and can only be arranged in a straight line.