- Home

- >

- News

- >

- Industry news

- >

- LTF Series Heavy - Duty Apron Feeder

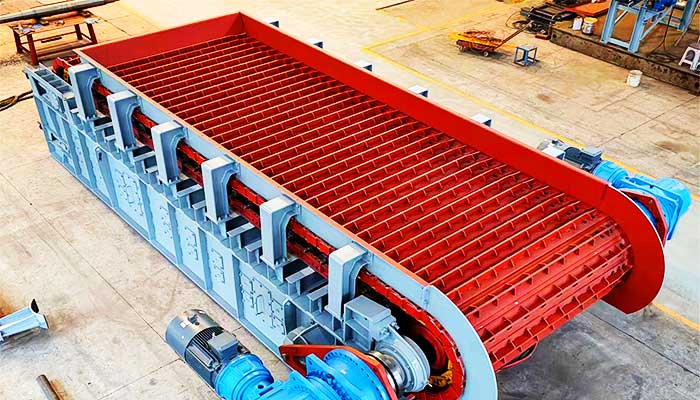

LTF Series Heavy - Duty Apron Feeder

In the competitive landscape of industrial material handling, the LTF series heavy - duty apron feeder emerges as a game - changer, addressing the diverse needs of industries like construction materials, metallurgy, and mining. Designed to seamlessly transfer lumpy or bulk materials from storage bins to crushers, conveyors, or other machinery—whether in horizontal or inclined setups—this feeder combines innovation with reliability, setting a new standard for efficiency.

Advanced Drive System for Optimal Performance

The LTF series is characterized by a high - performance variable - frequency speed - regulating motor directly connected to a planetary gear reducer. This configuration not only simplifies the structure but also boosts transmission efficiency. With the variable - frequency speed - regulating device, operators can achieve stable control over feeding volume, adapting to fluctuating loads and material characteristics. The power configuration and constant torque output ensure uniform material feeding for supporting equipment, promoting smooth operation and system automation. This flexibility caters to a wide range of production demands, making it a versatile choice for modern industrial setups.

Space - Saving and Stable Drive Design

One of the standout features is its drive unit, which requires no foundation. Using a single - point floating support, it directly hangs on the main shaft, ensuring easy installation. The reducer adopts a straight - through intersecting planetary hard tooth surface combination, lubricated by oil sump, with braking protection for reverse self - locking. The output shaft end uses a locking disc connection, enhancing concentricity. This design minimizes the feeder’s lateral dimensions, ideal for spaces where footprint matters.

Durability - Boosting Structural Innovations

Maintenance - Friendly Shaft and Bearing

The main shaft, bearings, and sprockets utilize expansion sleeves and removable couplings. This design avoids stress from keyways, protects the shaft neck, and simplifies installation and maintenance.

Robust Chain and Sprocket System

The active sprocket adopts a detachable drive tooth block for bulldozers, paired with a bulldozer - specific track chain. This ensures safe, reliable operation without frequent lubrication. The conveying plate, made of manganese steel with a stamped - welded structure, offers high rigidity, impact resistance, and tight sealing—eliminating issues like material leakage, scattering, or deviation. Precision assembly, welding, and mechanical processing guarantee accurate plate connections, while the high - strength, wear - resistant design ensures a service life of over three years.

High - Quality Sprocket Material

The sprockets, crafted from high - strength alloy steel and quenched, deliver exceptional wear resistance.

Smart Support Structure

The chain and plate support system uses a combination of weight rollers and idler rollers. This design offers high rigidity, impact resistance, and low operating resistance. The buffer device in the feeding section reduces impact on the plate, extending its lifespan and that of the entire machine.

Long - Lasting Lubrication

Both the weight roller and idler roller use 40Cr material, heat - treated and quenched. Grease lubrication ensures one - time oil injection lasts a year, with optional oil gun refilling during overhauls.

Adaptability for Diverse Setups

Tailored to real - world needs, the LTF series offers flexible installation options. Whether horizontal or with a large foot landing (maximum inclination of 25°), it minimizes civil engineering work, providing practical solutions for various sites.

In an industry where efficiency and durability are non - negotiable, the LTF series heavy - duty apron feeder stands out as a testament to innovative engineering. By integrating advanced technologies and user - centric designs, it not only meets but exceeds the demands of modern material handling—positioning itself as a top choice for businesses aiming to optimize productivity while ensuring long - term reliability. As industries evolve, the LTF series is poised to lead the way in redefining heavy - duty feeding solutions.