- Home

- >

- News

- >

- Company news

- >

- Efficiency gains: the new belt feeder

Efficiency gains: the new belt feeder

Efficiency gains: the new belt feeder

In order to increase productivity, it is advisable to replace the traditional Apron Feeder with a belt feeder for high moisture aggregate conveying applications.

Apron Feeders have long been the preferred choice for conveying materials in a variety of industries due to their robustness and ability to handle heavy loads. However, these feeders were not always ideal in applications with high aggregate moisture content, which led to operational challenges such as material clogging and reduced efficiency.

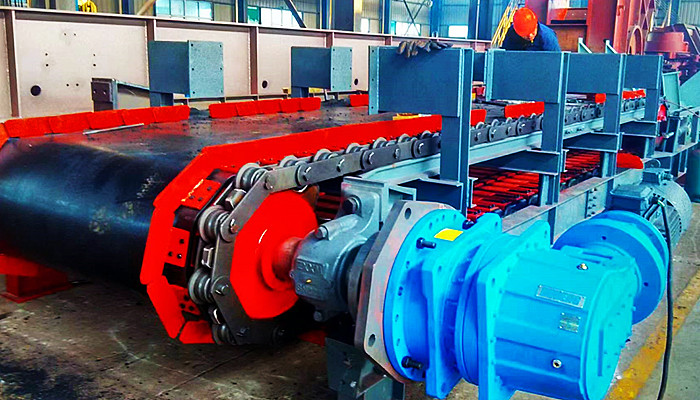

In recognition of the need for a more efficient solution, CAFU has developed a new belt feeder that offers superior performance in high moisture environments. Our belt feeder conveying system consists of a combination of support chain plates, baffles and wear resistant conveyor belts. The use of wear resistant conveyor belts to convey materials provides an effective and reliable conveying method.

One of the main advantages of the new belt feeders over the Apron Feeder in applications with high aggregate moisture levels is their ability to handle wet and sticky materials without clogging. The smooth surface of the belt prevents material sticking and ensures a constant flow rate. The baffles on the conveyor belt then provide support for large angle conveying, preventing material backflow and minimizing downtime due to blockages. This is particularly beneficial in industries such as mining, construction and cement production, where wet aggregates are commonly encountered.

In addition, the new belt feeders offer better accuracy in material handling. The continuous belt movement enables precise control of the feed rate, ensuring consistent and uniform material distribution. This feature is particularly valuable in applications where precise mixing or batching is required, for example in concrete production or fertiliser blending plants.

In addition to its superior performance in high humidity environments, the new belt feeder also boasts easy maintenance and reduced operating costs. The modular design of the belt allows for easy replacement of damaged parts, minimizing downtime and maintenance costs The new construction design also reduces power consumption, contributing to overall energy savings.

The adaptation from the Apron Feeder to the new belt feeder can overcome the challenges posed by high moisture materials for a wide range of owners. The adoption of the new belt feeder will not only improve operational efficiency, but will also increase overall productivity to reduce production costs.

For more information or enquiries about the adoption of the new belt feeder in high moisture aggregate conveying applications, please contact CAFU Company at sales@xmcfu.com.