- Home

- >

- News

- >

- Company news

- >

- Aluminum Ash Pneumatic Conveying

Aluminum Ash Pneumatic Conveying

Aluminum Ash Pneumatic Conveying

Aluminum ash is a primary and secondary aluminum industry manufacturing process of waste gas material, by alumina through the electrochemical method of melting metal and aluminum metal in the ingot casting, multiple remelting, parts casting and other processes generated by the aluminum ash is called white ash. Aluminum scrap after crushing, drying made of an off-white powder material, containing a large number of alumina, aluminum hydroxide, iron oxide, calcium oxide and other components, but also contains harmful metal elements, such as antimony, arsenic, lead, etc., a little carelessness will cause damage to the environment and human beings.

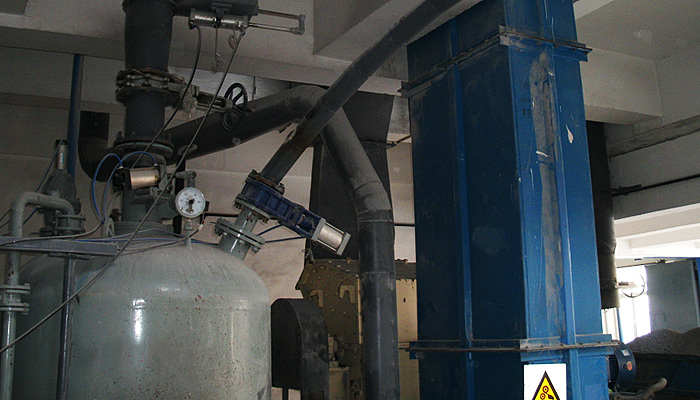

With the development of science and technology, aluminum ash has been applied, that is, energy saving and environmental protection, but also to reduce costs and improve economic efficiency. For example, alumina is one of the main components in aluminum ash, with high melting point and hardness, it can be used to manufacture ceramics, abrasive materials, electronic components, high-temperature materials and so on. Our customer will add aluminum ash in the refractory batching, the accumulation density is 0.9t/m³, conveying capacity is 10t/h, horizontal conveying distance is 600m, vertical conveying distance is 30m, and there are 10 elbows, CAFU Machinery customized Bin Pump aluminum ash pneumatic conveying, in order to guarantee the stable operation of the system, 5 assistant blowing devices are set up on the conveying pipeline, this system consists of silo, The system consists of silo, service valve, pneumatic plug valve, silo pump, conveying pipeline, silo dust collector, PLC control and other pneumatic conveying equipment, is a batch dense phase conveying system.

This aluminum ash Bin Pump pneumatic conveying work process:

(1) feeding stage: feed valve and exhaust valve open, aluminum ash from the bottom of the silo unloading port free fall into the tank inside, when the height of aluminum ash rises to the specified weight, the level meter sends out a signal, the feed valve and exhaust valve automatically closed to complete the feeding process.

(2) Pressurized fluidization stage: the air inlet valve group opens, compressed air into the tank, diffusion through the fluidized bed, the bottom of the aluminum ash inflatable fluidization, the tank internal pressure rises, slowly rising to the high pressure value of the pressure gauge settings.

(3) conveying stage: the pressure inside the tank rises slowly, reaching the set high pressure limit, the pressure gauge sends out a signal, the discharge valve opens automatically, and the conveying starts, and the aluminum ash inside the tank reduces gradually, at this time, the materials on the fluidized bed are always dealt with while fluidizing and conveying until the conveying is completed.

(4) blowing stage: when the tank internal aluminum ash conveying is completed, the pressure in the pipeline drops to the lower limit set by the pressure gauge, the pressure gauge sends out a signal, delayed ventilation for a period of time, the use of compressed air to clean up the pipeline, and then close the inlet valve group, delay a certain amount of time, close the discharge valve, open the exhaust valve, delay a certain amount of time, open the inlet valve, feed the material to complete the cycle of a conveyor.

Bin Pump aluminum ash pneumatic conveying advantages:

1. It is suitable for dispersed conveying materials from one point to many points.

2. low conveying speed, less wear and tear of pipeline, small crushing degree of the material being conveyed, which is especially favorable for the conveying of brittle and fragile materials.

3. high mixing ratio conveying in the conveying pipe, high conveying efficiency;

4. low gas consumption, reduce energy consumption, tail gas treatment equipment is simple, small size;

5. it can also be conveyed in the place where back pressure exists.

According to the customer site process and demand for pneumatic conveying manufacturers to suit the local conditions, and sometimes also use negative or positive pressure and other dilute-phase aluminum ash pneumatic conveying system, our company has many years of engineering design, manufacturing, installation, commissioning and operation experience, and free design of various powder and granular materials pneumatic conveying system program, if you need to please feel free to contact us.