- Home

- >

- News

- >

- Company news

- >

- Stainless Steel Silo of PET Pellets

Stainless Steel Silo of PET Pellets

Stainless Steel Silo of PET Pellets

The storage of PET pellets needs to be completely sealed, protected from sun and rain, and kept away from UV rays. At the same time, the storage silo should not be connected to the air because PET pellets absorb moisture. In order to ensure the effectiveness of the silos and to avoid the exposure of the PET pellets to moisture, the bolt silos have to be manufactured in such a way that they are completely sealed.

Most of the PET pellet storage silos on the market are made of stainless steel with integral welding, and most of them have a volume of less than 200m³ because they are limited by transportation. For larger storage capacity, on-site construction is required. On-site construction poses additional management problems for plastic manufacturers and recyclers. Therefore, bolted stainless steel silos with good sealing conditions have become a good choice for plastic manufacturers and plastic recyclers.

Compared with the corrugated stainless steel silo for PET bottle flakes (PET bottle flakes can not be used as raw material for product production because of further processing, and its storage requirements are relatively less strict), the stainless steel bolted silo has better sealing effect and good storage conditions. All sealing materials are made of food-grade silicone rubber, which ensures that all contact surfaces are protected by good hygiene. It is one of the best choices for storing PET pellet materials.

The stainless steel bolted silo is completely modularized in the factory to meet container size shipping requirements and will be installed and put into service at the plastics production plant much faster than a monolithic welded silo manufactured on site.

Since PET material is widely used in the production of food containers, the cleanliness requirements for silos are strict. In general, PET stainless steel storage silos are manufactured from 304 or 316 stainless steel with mirror finish on the inner surface and brushed on the outer surface. After the modular processing is completed, before leaving the factory, the surface is cleaned and protected by packaging to prevent surface contamination.

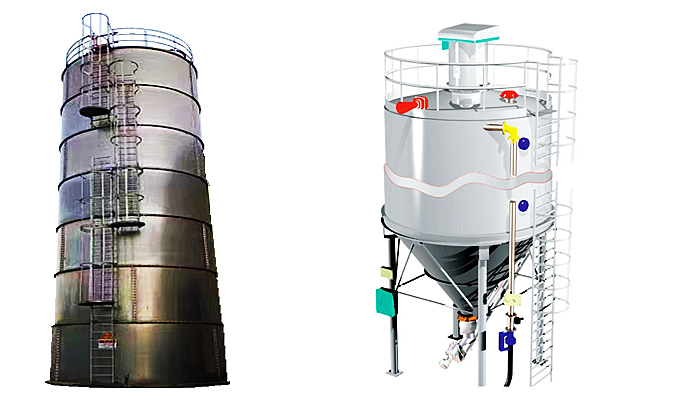

Due to the good fluidity of PET pellets, the design and manufacture of silos need to consider the negative pressure deformation of silo walls. stainless steel bolted silos of CAFU are designed with strict scientific calculations and equipped with a full set of silo safety control system (see figure) to ensure the absolute safety of silos in use.

To sum up, when choosing PET pellet large-capacity storage silo, you should choose stainless steel bolted silo with good sealing, excellent manufacturing process and reasonable design.