- Home

- >

- Products

- >

- Powder Pneumatic Conveying System

- >

- Dense Phase Pneumatic Conveying System

Dense Phase Pneumatic Conveying System

Product origin :China

In the dynamic landscape of industrial material handling, dense phase pneumatic conveying systems have emerged as a revolutionary solution, offering unparalleled efficiency and reliability for transporting bulk solids.

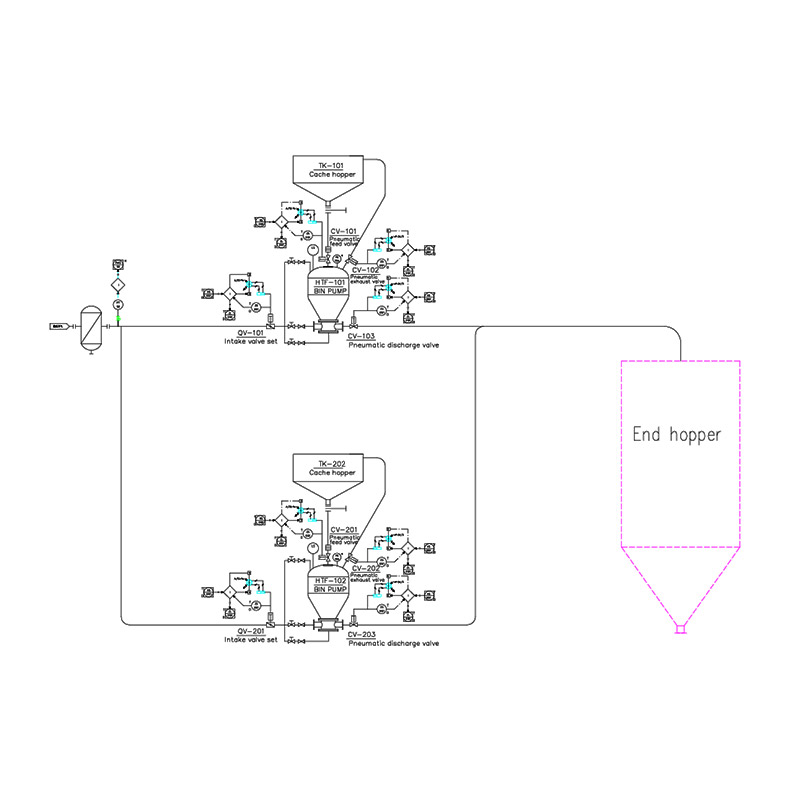

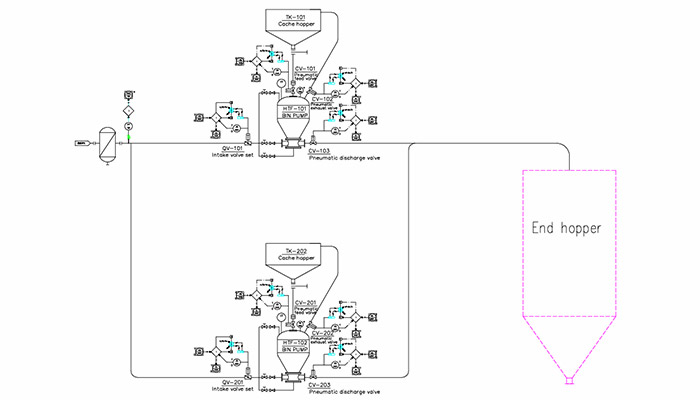

Dense phase pneumatic conveying is a sophisticated method of transporting bulk materials, such as powders, granules, and pellets, through enclosed pipelines using compressed air or gas. Unlike dilute phase systems, which rely on high - velocity air streams to suspend materials, dense phase conveying operates at lower velocities, allowing materials to move in a slug - like or fluidized state. This unique approach minimizes product degradation, reduces wear on system components, and enables the transportation of abrasive, fragile, or high - density materials over long distances.

Key Components of a Dense Phase Pneumatic Conveying System

1. Feeding Device: The feeding device plays a crucial role in metering and introducing materials into the conveying pipeline. Common feeding devices include rotary valves, screw feeders, and airlock valves, each designed to handle specific material characteristics and flow rates.

2. Conveying Pipeline: The conveying pipeline is the backbone of the system, providing a sealed pathway for material transport. Pipelines are typically constructed from stainless steel, carbon steel, or specialty alloys to withstand high pressures and resist abrasion.

3. Compressed Air Source: A reliable compressed air source, such as a compressor or blower, supplies the necessary pressure to propel materials through the pipeline. The compressed air is carefully regulated to maintain optimal conveying conditions and prevent material segregation or blockages.

4. Discharge Device: The discharge device separates the conveyed materials from the compressed air at the destination point. Cyclone separators, bag filters, and dust collectors are commonly used discharge devices to ensure efficient material recovery and minimize dust emissions.

5. Control System: The control system monitors and regulates the operation of the dense phase pneumatic conveying system, ensuring safe and efficient performance. Advanced control systems incorporate sensors, programmable logic controllers (PLC), and human - machine interfaces (HMI) to optimize conveying parameters, detect faults, and provide real - time diagnostics.

Advantages of Dense Phase Pneumatic Conveying Systems

1. Reduced Product Degradation: The low - velocity operation of dense phase conveying minimizes the impact and friction between materials and pipeline walls, reducing the risk of product degradation, breakage, or fines generation. This makes dense phase systems particularly suitable for transporting sensitive or fragile materials, such as pharmaceuticals, food products, and fine chemicals.

2. Lower Energy Consumption: Compared to dilute phase systems, dense phase conveying requires less compressed air to transport the same amount of material. This results in significant energy savings, especially for long - distance conveying applications.

3. Minimal Wear and Tear: The gentle handling of materials in dense phase systems reduces wear on system components, such as pipelines, elbows, and valves. This extends the lifespan of the equipment, reduces maintenance costs, and minimizes downtime.

4. Versatility: Dense phase pneumatic conveying systems can handle a wide range of materials, including powders, granules, pellets, and even some liquids. They can also be customized to meet specific application requirements, such as conveying distance, material flow rate, and operating pressure.

5. Improved Safety and Hygiene: The enclosed nature of dense phase conveying systems prevents dust emissions, spills, and contamination, creating a safer and more hygienic working environment. This is particularly important for industries such as food processing, pharmaceuticals, and chemical manufacturing.

6. Enhanced Process Control: Advanced control systems used in dense phase conveying systems provide precise control over conveying parameters, such as air pressure, flow rate, and material level. This allows for greater process flexibility, improved product quality, and reduced waste.

Applications of Dense Phase Pneumatic Conveying Systems

1. Food and Beverage Industry

2. Pharmaceutical Industry

3. Chemical Industry

4. Mineral Processing Industry

5. Power Generation Industry

6. Plastics Industry

Dense phase pneumatic conveying systems offer a powerful and efficient solution for transporting bulk materials across various industries. Feel free to contact the CAFU service team to customize the most cost - effective solutions tailored to your bulk material handling needs.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more