- Home

- >

- Products

- >

- Powder Pneumatic Conveying System

- >

- Dilute Phase Pneumatic Conveying System

Dilute Phase Pneumatic Conveying System

Product origin :China

In the world of bulk solids handling, pneumatic conveying systems play a crucial role. Among them, dilute phase pneumatic conveying is a widely used method with its own set of characteristics, applications, and considerations.

What is Dilute Phase Pneumatic Conveying System?

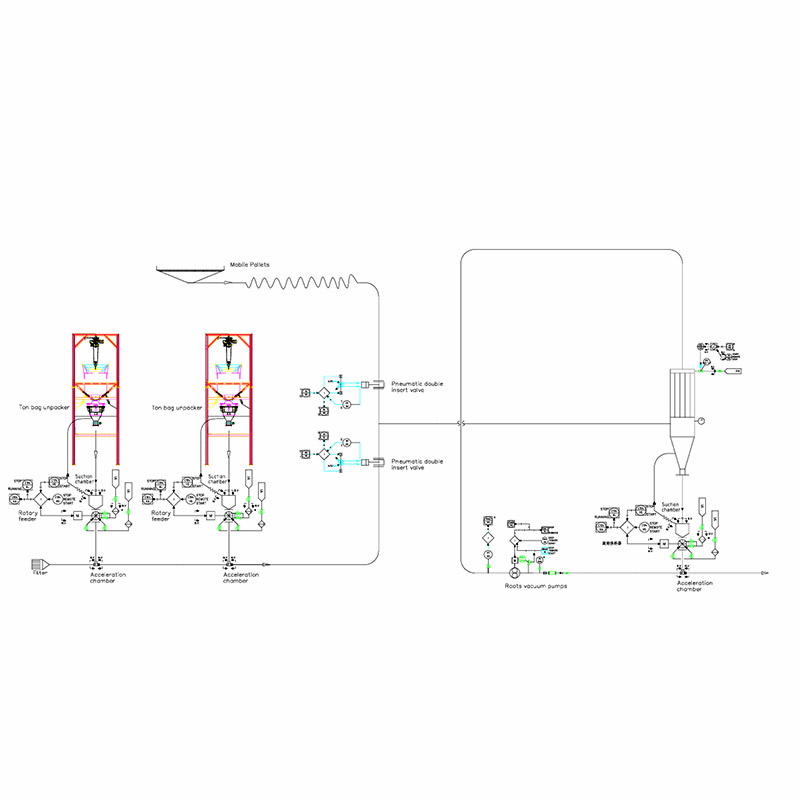

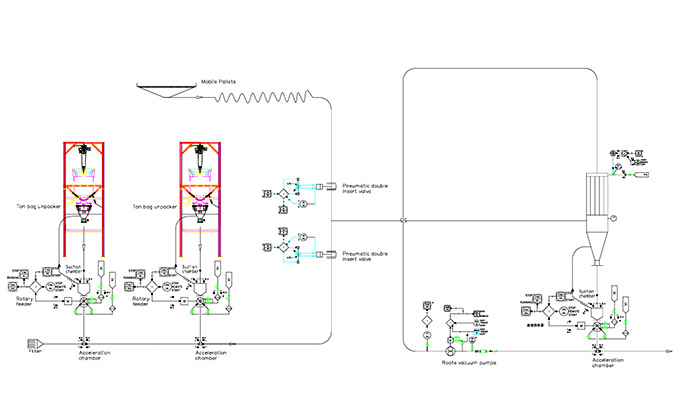

Dilute phase pneumatic conveying is a technique used to transfer dry bulk solids between silos or other storage and processing units through enclosed, airtight pipes. The medium for transportation is gas, typically air. In this system, materials are continuously metered into the airstream. This is often achieved using a rotary airlock or a similar component.

One of the defining features of dilute phase pneumatic conveying is the high - velocity air streams it employs. These high - speed air flows keep the materials suspended within the pipe, as opposed to the dense phase systems where materials may accumulate or be dragged along the bottom of the pipe. Due to this suspension mechanism, dilute phase pneumatic conveying is particularly well - suited for transporting lightweight, low - density materials.

Types of Dilute Phase Pneumatic Conveying

1. Dilute Phase Pressure Conveying

In a dilute phase pressure conveying system, a blower or compressor is positioned at the start of the conveying line. Its role is to supply a large volume of low - pressure air. When bulk materials are introduced into the system, they enter the high - velocity airstream and are then pushed through the pipes. Once the materials reach their intended destination, they are separated from the airstream. This separation is typically accomplished using a filter receiver or a cyclone.

This type of dilute phase system is commonly used when there is a single source or pickup point for the materials, but multiple destinations are involved. It is an excellent choice for conveying non - abrasive, non - fragile materials. Materials with a bulk density of less than 62 lb/ft³ are particularly suitable for this method. Some examples of materials conveyed using dilute phase pressure conveying include sugar, starch, plastic granules, sodium bicarbonate, hydrated lime, activated carbon, and zinc oxide.

2. Dilute Phase Vacuum Conveying

Contrary to the pressure - based system, a dilute phase vacuum conveying system has a suction device located at the end of the line. This creates a negative pressure or a vacuum within the pipes. The vacuum then pulls the materials along with the airstream to their destination.

Vacuum systems are popular in facilities where there are multiple pickup points, but only one main destination area. They are especially useful for materials that tend to pack or compress under pressure, such as wood shavings. Additionally, since they allow for tight control over hazardous particles, dilute phase vacuum systems are ideal for moving toxic materials where any leakage must be strictly prevented.

Materials Suitable for Dilute Phase Pneumatic Conveying

Dilute phase pneumatic conveying systems are designed to move particles at high speeds while they are suspended in a powerful airstream. As a result, they are best utilized for lightweight, non - abrasive materials. This includes materials with fine or granular particles and those with a low bulk density.

Common materials that can be processed using a dilute phase pneumatic conveying system are numerous. In the food industry, items like flour, sugar, and coffee beans can be transported. In the chemical and manufacturing sectors, materials such as bleaching earth, chemical powders, high - density polyethylene (HDPE) powders, lime, pigments, resins, and soda ash are suitable candidates. Fly ash, which is a by - product of coal combustion in power plants, can also be conveyed using this method. Additionally, materials like talc and wood shavings can be effectively transported through dilute phase pneumatic conveying systems.

Benefits of Dilute Phase Pneumatic Conveying

1. High Versatility

2. Long - Distance Conveying

2. Easy to Operate and Install

4. Easy to Clean and Maintain

5. Lower Capital Investment

If you need to learn more about the performance requirements of dilute phase pneumatic conveying systems or customize high - quality pneumatic conveying systems for your facilities, please feel free to contact the CAFU service team.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more