- Home

- >

- Products

- >

- Bulk Material Conveying Equipment

- >

- Grain Bucket Elevators for Feed and Grain Processing

Grain Bucket Elevators for Feed and Grain Processing

Product origin :China

CAFU Grain Bucket Elevators are engineered for reliable vertical conveying in feed processing and grain processing industries, featuring non-standard customization to meet unique project needs. With a maximum lifting height of 50 meters and a flexible capacity range of 1-150 tons per hour, these elevators deliver powerful performance and long-lasting durability.

Grain Bucket Elevators: High-Capacity Vertical Conveying Solution for Feed & Grain Processing

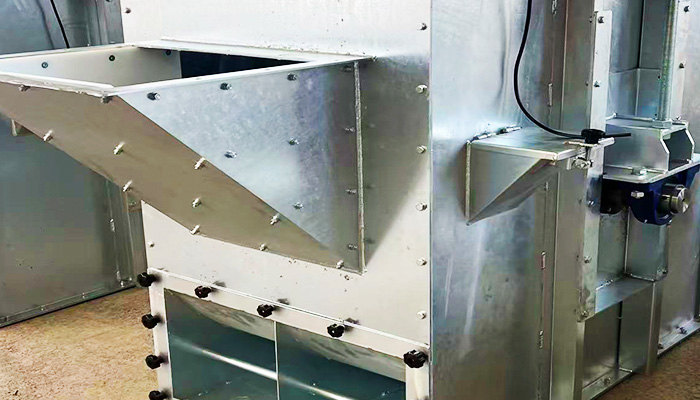

Key advantages include heavy-duty rubber belts, wear-resistant nylon liners in head and boot structures, angle steel flange connections for stability, and high-quality heavy-duty pillow block bearings. Corrosion protection is tailored to usage environments—powder coating for indoor applications and galvanization as standard for outdoor use—ensuring consistent operation in harsh or humid conditions. Ideal for bulk grain and feed handling, our elevators combine efficiency, durability, and adaptability to boost your production workflow.

As a core equipment in bulk material handling, our Grain Bucket Elevators are specifically designed to address the vertical conveying demands of feed processing plants and grain processing facilities. Whether you need to transport corn, wheat, soybeans, or compound feed, these elevators offer a seamless, high-efficiency solution with customizable configurations to fit your site layout and capacity requirements. From small-scale 1 TPH systems to large industrial 150 TPH setups, we prioritize structural integrity, wear resistance, and corrosion protection to ensure long service life and minimal maintenance.

Core Features & Advantages

1. Non-Standard Customization

We offer full non-standard customization to adapt to your unique project constraints—including adjusted lifting height, bucket size, belt speed, and installation layout. Our engineering team works closely with you to tailor the elevator to your specific conveying needs, ensuring perfect integration with existing production lines.

2. 50m Ultra-High Lifting Height

Designed with a maximum lifting height of 50 meters, our elevators excel in tall silos, multi-story processing plants, and large-scale storage facilities. The robust structural design ensures stability even at extreme heights, eliminating material spillage and ensuring consistent conveying performance.

3. Powerful Driving Force

Equipped with high-efficiency motors and precision gearboxes, our elevators deliver powerful, energy-saving operation. The optimized drive system provides sufficient torque to handle heavy bulk loads, even at maximum capacity and lifting height, ensuring smooth, uninterrupted material flow.

4. High-Grade Rubber Belts

We use premium heavy-duty rubber belts that offer excellent tensile strength, flexibility, and wear resistance. The belts are designed to withstand continuous friction and heavy bucket loads, reducing replacement frequency and downtime.

5. Wear-Resistant Nylon Liners (Head & Boot Structures)

Both the head and boot structures are fitted with high-quality wear-resistant nylon liners. These liners minimize friction between the bucket and structural components, reduce material degradation, and extend the service life of the elevator—critical for long-term cost savings.

6. Angle Steel Flange Connections

The elevator trunking adopts angle steel flange connections, ensuring exceptional structural rigidity and alignment. This design enhances stability, prevents deformation during operation, and simplifies installation and maintenance.

7. High-Quality Heavy-Duty Pillow Block Bearings

We integrate top-grade heavy-duty pillow block bearings that provide superior load-bearing capacity and resistance to wear. The sealed design protects against dust and moisture, ensuring reliable operation in harsh industrial environments with minimal lubrication needs.

8. Tailored Corrosion Protection

● Indoor Use: Standard powder coating finish offers excellent corrosion resistance for dry, indoor environments, maintaining a clean, professional appearance.

● Outdoor Use: Default hot-dip galvanization treatment provides robust protection against rain, humidity, and atmospheric corrosion, extending service life in outdoor or exposed installations.

Applications

Our Grain Bucket Elevators are widely trusted in two core industries:

● Feed Processing Industry: Ideal for conveying raw materials (soybean meal, corn gluten meal, premixes) and finished feed products between processing stages, storage silos, and packaging lines.

● Grain Processing Industry: Perfect for handling wheat, corn, rice, barley, and other grains in flour mills, rice processing plants, grain storage terminals, and food processing facilities.

Technical Specifications

Parameter | Details |

Product Type | Grain Bucket Elevator |

Lifting Height | Maximum 50 meters (customizable) |

Capacity Range | 1-150 tons per hour (TPH) |

Customization | Full non-standard design (height, capacity, layout) |

Belt Quality | High-grade heavy-duty rubber |

Wear-Resistant Components | Nylon liners (head & boot structures) |

Structural Connection | Angle steel flange |

Bearings | High-quality heavy-duty pillow block bearings |

Corrosion Protection | Indoor: Powder coating; Outdoor: Hot-dip galvanization (standard) |

Application Industries | Feed processing, Grain processing |

Why Choose Our Grain Bucket Elevators?

● Proven Durability: Wear-resistant components and robust structural design reduce maintenance costs and extend service life.

● Flexible Adaptability: Non-standard customization and wide capacity range meet diverse project needs.

● Reliable Performance: Powerful drive systems and high-quality bearings ensure stable operation even under heavy loads.

● Tailored Protection: Environment-specific corrosion treatments guarantee performance in indoor and outdoor settings.

● Industry Expertise: Engineered specifically for feed and grain processing, ensuring compatibility with industry workflows.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more