- Home

- >

- Products

- >

- Bulk Material Conveying Equipment

- >

- High Performance LTC65 Tracked Conveyor

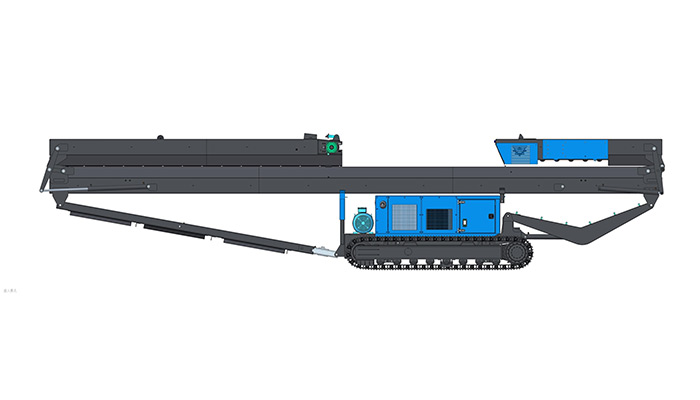

High Performance LTC65 Tracked Conveyor

Product origin :China

The LTC-65 Tracked Conveyor is a flagship model in the LTC series of mobile conveyors, designed to work seamlessly with crushing and screening equipment. It combines a 20m conveyor length, 1000mm belt width, and 400 TPH conveying capacity to boost stockpile volume up to 1300 m³, while features like diesel-hydraulic drive, 40ft HC container compatibility, and customizable add-ons deliver cost savings, efficiency, safety, and environmental compliance for diverse job sites.

The LTC-65 Tracked Conveyor is part of the LTC range of mobile conveyors, engineered specifically to integrate with crushing and screening equipment . Its core value lies in optimizing material handling workflows: it increases stockpile capacity, reduces on-site material movement, and cuts reliance on wheel loaders—ultimately lowering operational costs and improving site safety . With a tracked design, it ensures stability on uneven terrain, making it ideal for industries like construction, mining, and aggregate processing where flexible, heavy-duty material transport is essential.

Technical Specifications

● Core Conveyor Parameters

Parameter | Details |

Conveyor Length | 20m |

Belt Width | 1000mm (plain belt as standard; Chevron belt optional) |

Drive System | Diesel-Hydraulic |

Max Discharge Height | 9m @24° |

Stockpile Volume | 1300 m³ @24°@37° angle of repose |

Conveying Capacity | 400 TPH |

Functional Adjustments | Hydraulic conveyor angle adjustment, hydraulic feed-in height adjustment, hydraulic folding for transport, variable speed control |

● Power Unit Details

Component | Specifications |

Power Type | Diesel Hydraulic |

Engine (Tier3) | 37.5kW (50Hp) |

Fuel Tank Capacity | 150L |

● Transport & Weight

Item | Value |

Machine Weight | 13,500 kg |

Transport Compatibility | Fits in 40ft HC container |

Key Features & Benefits

Category | Features & Benefits |

Cost Reduction | 1. Reduces wheel loader use to lower fuel and maintenance costs |

Site Efficiency | 1. Works with crushing/screening equipment for seamless workflow |

Safety | 1. Fewer wheel loaders reduce on-site collision risks |

Environmental Compliance | 1. Optional water dust suppression system reduces dust emissions |

Customizable Optional Add-Ons

Optional Feature | Description |

Dual Power System | 30kW motor + electrical cabinet to drive the hydraulic pump |

Full-Length Rubber Skirting | Full-size rubber skirting for the conveyor belt (prevents material leakage) |

Chevron Belt | Conveyor belt with Chevron pattern (improves grip on slippery materials) |

Water Dust Suppression System | System with water pump to suppress dust during operation |

Custom Paint Colours | Special colours available (RAL code must be specified when ordering) |

Important Notes

● Specification Updates: All reasonable steps ensure the accuracy of this information, but specifications may be changed without prior notice due to continuous product development .

● Local Compliance: Importers are responsible for verifying that the equipment meets local regulatory requirements .

● Performance Data: Factory performance figures (e.g., 400 TPH capacity) are for illustration only; actual results may vary based on raw material grade and characteristics, and this data is not legally binding.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more

-

Download

- LTC65 TRACKED CONVEYOR.pdf