- Home

- >

- Products

- >

- Spare Parts for Bulk Material Handling Equipment

- >

- High-Quality Wear Resistant Spare Parts for Pulverizer

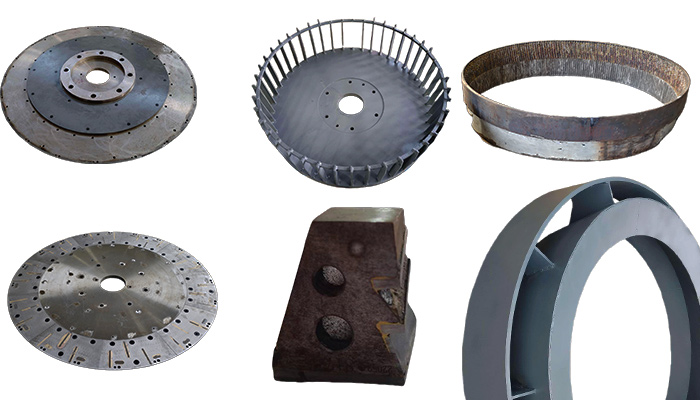

High-Quality Wear Resistant Spare Parts for Pulverizer

Product origin :China

Feed ultra-fine pulverizers are key for making high-quality aquafeed (shrimp, fish feed) and livestock feed. Their spare parts need to resist wear from grain, soybean meal, and mineral additives, while ensuring fine, even powder (60–100 mesh) for better feed digestibility. Our parts are tailored for this, focusing on durability and easy maintenance to keep feed production running smoothly.

Premium Spare Parts for Feed Ultra-Fine Pulverizer: Boost Production Efficiency

1. Core Spare Parts for Feed Ultra-Fine Pulverizer

1.1 Dual-Stage Grinding Hammer Head

The main crushing part, designed to grind feed twice for finer powder.

● Material: High-strength cast steel (ZG270-500) with wear-resistant alloy welded to the tail.

● Advantages: 30% more wear-resistant than standard heads; boosts output by 15% and ensures ≥90% of shrimp feed passes 60 mesh. Balanced weight (error ≤5g) to avoid machine vibration.

● Use For: Grinding soybean meal, corn, and mineral mixes in aquafeed/livestock feed lines.

1.2 Split Wear-Resistant Ring

Works with hammer heads to boost crushing force, great for tough feeds like expanded aquafeed.

● Material: High-quality steel with wear-resistant alloy on the inner surface.

● Advantages: Split design cuts maintenance time by 50% (no full machine disassembly); lasts up to 11,000 tons for expanded/shrimp feed. Smooth surface prevents feed buildup.

● Use For: Ultra-fine grinding of expanded feed and high-mineral livestock feed.

1.3 Split Wear Plate (NM500 Steel)

Protects the pulverizer chamber and guides feed flow, avoiding uneven wear.

● Material: Laser-cut NM500 steel (hardness ≥500 HB) with alloy at key stress points.

● Advantages: Reduces powder friction by 40% (saves energy); split design lets you replace only worn sections.

● Use For: Grinding mineral-rich feed (e.g., layer feed with limestone) and abrasive materials like peanut meal.

1.4 High-Speed Drive Disk

Transmits power to keep the pulverizer running at stable speeds (2800–12,000 R/Min).

● Material: 45# steel with tungsten carbide overlay on the outer circle.

● Advantages: Resists wear from feed powder; balanced (error ≤5g) to avoid vibration and ensure even powder. Easy to install via dedicated threaded holes.

● Use For: Continuous feed production lines needing steady grinding speed.

1.5 Precision Classifying Wheel

Controls powder fineness, critical for small feed like shrimp larvae feed.

● Material: Thick steel plate (16mm) and round steel (φ14mm), laser-cut and welded.

● Advantages: Separates oversize particles (sends them back to grind) and discharges qualified powder (60–100 mesh). Anti-rust surface handles moist feed.

● Use For: Aquafeed and high-end livestock feed requiring strict fineness.

1.6 Other Essential Parts

● Feed Flow Divider Cover: Guides feed evenly into the chamber to prevent uneven hammer wear; made of food-safe steel.

● Main Shaft Assembly: High-strength 40Cr steel shaft + high-speed bearings + dust seals; ensures stable power for 24/7 production.

● Pin Discs: For ultra-fine grinding of herbal additives/probiotics in livestock feed; wear-resistant alloy steel.

2. Why Choose Our Parts?

● Feed-Specific: Not repurposed from other industries—built for feed materials.

● Long-Lasting: Wear-resistant materials (NM500 steel, alloy) extend replacement cycles by 30–50%.

● Easy Maintenance: Split designs and user-friendly features cut downtime.

● Wide Fit: Works with most mainstream feed ultra-fine pulverizer models (small 5–50 kg/h to large 5–20 T/h lines).

3. Application Scenarios

● Aquafeed: Split rings + classifying wheels ensure 60–100 mesh powder for better shrimp/fish digestion.

● Livestock Feed: Dual-stage hammer heads + wear plates handle fiber (straw) and minerals.

● Expanded Feed: Wear-resistant rings + drive disks process tough expanded feed efficiently.

Contact Us Now

Get parts tailored to your feed line. Share your pulverizer model and production needs for fast delivery.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more