- Home

- >

- Products

- >

- Bulk Material Conveying Equipment

- >

- Permanent Magnet for Belt Conveyor

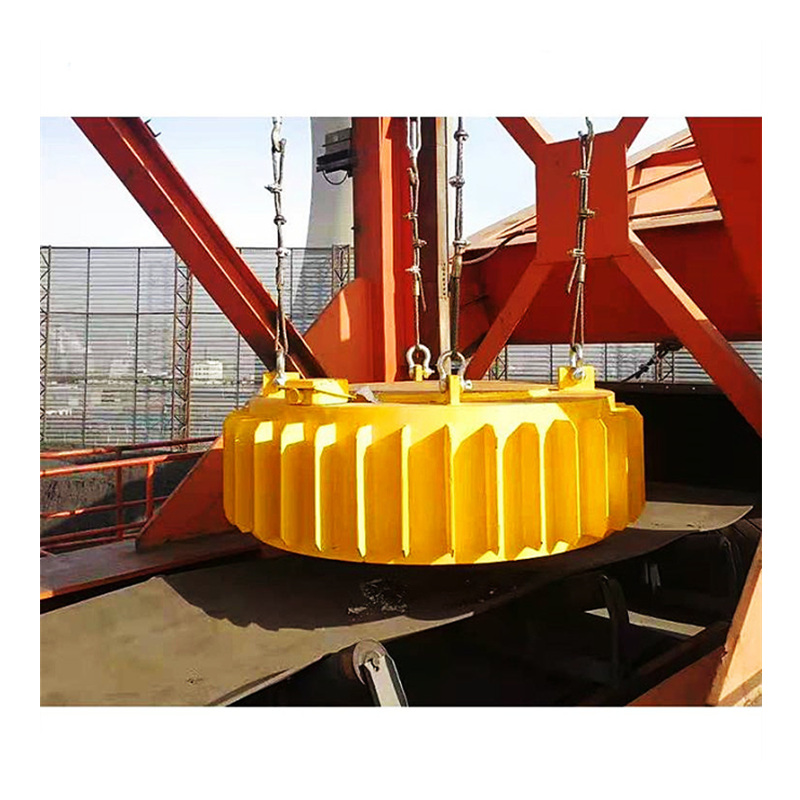

Permanent Magnet for Belt Conveyor

Brand :Cafu

Product origin :China

RCDB Dry Electromagnetic Separator and RCDD Electromagnetic Self-Unloading Separator

Scope of application:

It is used to remove iron from any material in front of the crusher and on the conveyor belt, and can be applied to various harsh environmental conditions.

Electromagnetic iron remover plays a key role in protecting terminal equipment from hard steel impurities in conveyed materials.

Technical characteristics of RCDB dry electromagnetic separator:

The magnetic circuit adopts computer simulation design, with deep magnetic permeability and strong magnetic force.

The interior adopts electrician special resin casting, self-cooling fully sealed structure, dust-proof, rain-proof and corrosion-resistant.

The wave-fin heat sink greatly increases the heat dissipation area and controls the temperature rise.

It can separate 0.1-50 kg of ferromagnetic materials.

Technical characteristics of RCDD electromagnetic self-unloading iron separator:

The magnetic circuit adopts computer simulation design, with large magnetic penetration depth and strong magnetic force.

The interior adopts electrician special resin casting, self-cooling fully sealed structure, dust-proof, rain-proof, salt spray-proof, and corrosion-resistant.

Automatic unloading of iron, easy maintenance, drum-shaped structure, automatic belt correction function, special fully sealed bearing seat, can achieve long-term trouble-free operation.

The product has good compatibility, the rectifier equipment has complete functions, manual and centralized control functions, which can meet the requirements of various occasions.

It can effectively separate 0.1-50 kg of ferromagnetic materials.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more