- Home

- >

- Products

- >

- Building Materials Machinery

- >

- Screening Machine

Screening Machine

Brand :Cafu

Product origin :China

CAFU has customized stone or rock vibrating screen equipment for many crushing and screening equipment company. In addition to custom stone vibrating screen equipment, we offer individual components including apron feeder and heavy duty vibrating screen.

Rock vibrating screen & stone vibrating screen used in stone crusher plant

Introduction to Crawler Type Heavy Duty Screening Stations

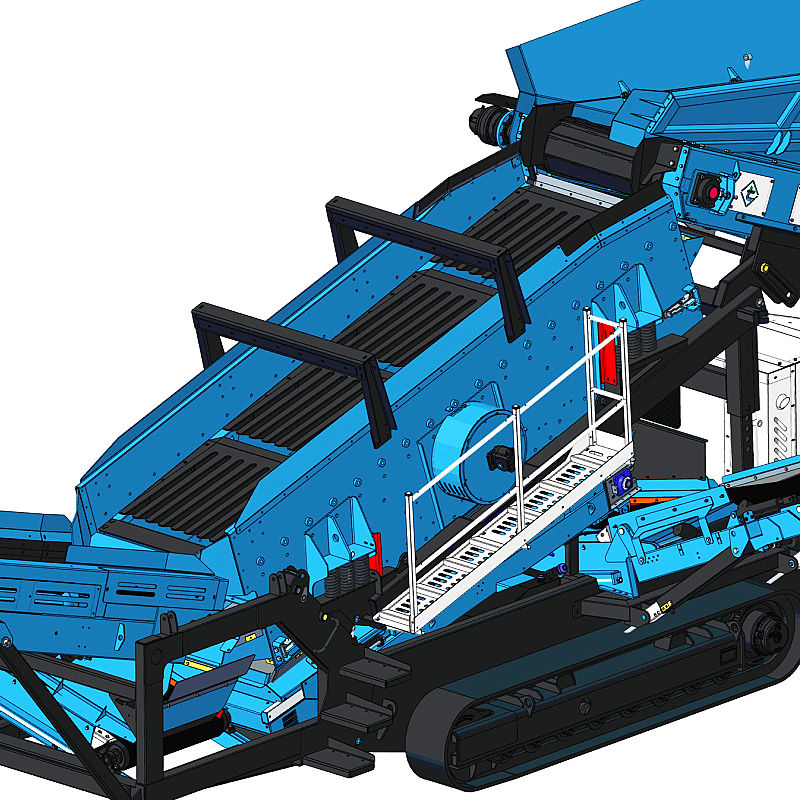

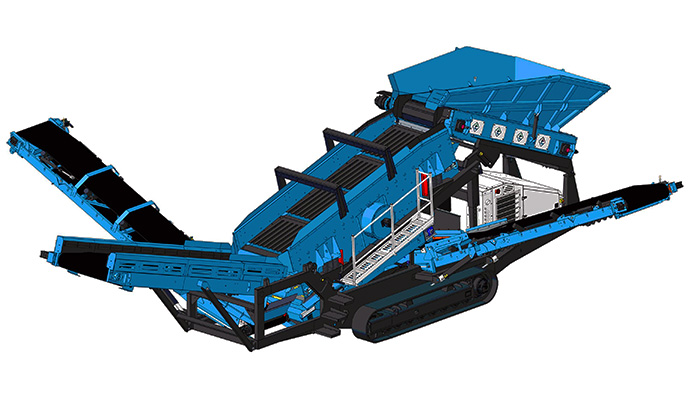

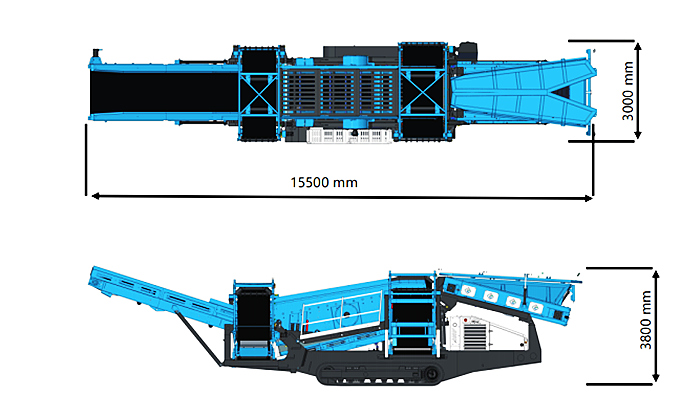

▌LTS2500 Crawler Heavy Duty Mobile Screening Station

※2 DECK HEAVY DUTY / INCLINE VIBRATING SCREEN

1. Scope of application

▌Aggregate Processing, Sand & Gravel Processing, Blasting Rock Processing, Cobblestone Processing

▌Topsoil, Construction Rubbish, Compost Aggregate, Wood -Products

▌Ore processing, Mineral Processing, Foundry Waste

2. Features and Benefits

1). Super processing capacity up to 500T/H (depending on the size and type of material);

2). The maximum material feeding size is 500mm, and the maximum feeding size of different materials may vary;

3). The equipment is equipped with a heavy-duty chain plate feeder as standard, and the hopper is hydraulically folded;

4). The hydraulic lifting screen box device facilitates access to the screen box for maintenance;

5). 10mm large amplitude double bearing screen box;

6). The track pressure on the ground is small;

7). Usually within 15 minutes from transportation to working condition;

8). The conveyors on both sides are hydraulically folded, which is convenient and fast;

9). High performance hydraulic system.

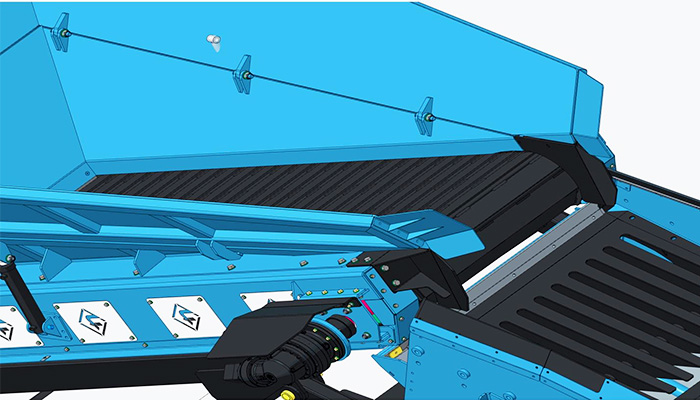

3. Apron feeder

1). The width of the chain plate is 1200mm

2). Driven by high torque reducer with adjustable feeding speed

3). Bucket volume: 6.8m³

4). Side feed height: 4.2m

5). Feeding height at the tail: 3.6m

6). Side hopper adopts hydraulic folding

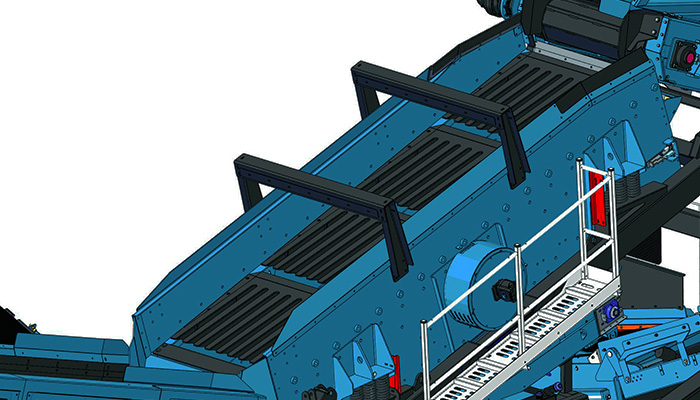

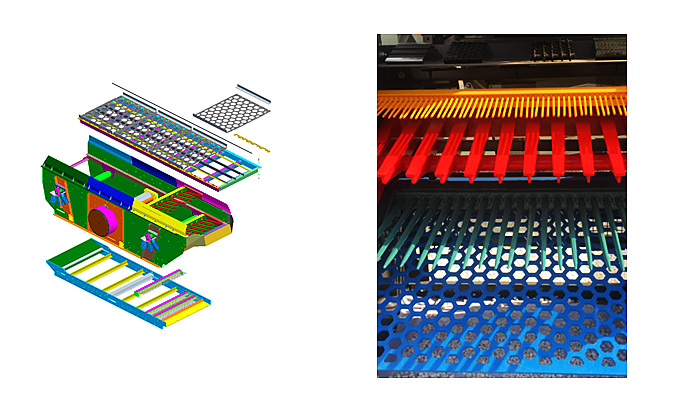

4.Heavy Duty Screening Machine

1). Double-layer screen box: 4.85mx1.54m

2). Large amplitude: 10mm

3). Top side pull screen tensioning or modular screen structure

4). Front and rear tensioning structure of bottom screen

5). Screen box angle hydraulic adjustment: 14° -18°

6). Hydraulic lift screen box, increase screen box maintenance space

7). Modular top sieves include: grate sieves, needle sieves, and punched sieves

5. Power Unit

1). Engine: Cummins National Stage Four Engine 118Kw @2200 rpm;

2). Pump: hydraulic pump imported from Italy;

3). The main hydraulic components are imported brands;

4). Control: PLC integrated control, fault alarm feedback

6. Shipping size

Total weight: 30.5 tons

CAFU Machinery is the source factory of stone or rock vibrating screen equipment, in addition to professional stone vibrating screen technology development capability, our vibrating screen products have good product quality and cost performance. If you happen to have a need for mobile rock vibrating screen equipment or parts, please feel free to contact us.

Customized design of general fabricated steel silo needs to provide: 1. Storage material name 2. Density of storage material 3. Storage material particle size 4. Storage capacity 5. Feeding method 6. Discharge method and size of discharge port 7. The height of the discharge port from the ground...more