- Home

- >

- News

- >

- Company news

- >

- New Tracked Conveyor for CAFU LTC Series

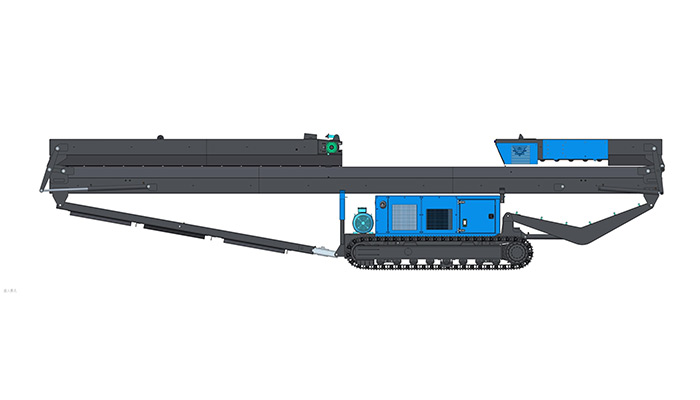

New Tracked Conveyor for CAFU LTC Series

CAFU Machinery Launches New Tracked Conveyor: A Core Addition to One-Stop Bulk Material Handling Solutions

As a leading provider of one-stop solutions for bulk material handling processes—including high-quality powder pneumatic conveying systems, crushing & mixing, and screening—CAFU Machinery is proud to announce the launch of our latest innovation: the Tracked Conveyor. This new equipment marks a significant enhancement to our comprehensive bulk material handling portfolio, reinforcing our commitment to delivering efficient, compliant, and industry-specific solutions for global clients.

CAFU Machinery: A Trusted Partner Across Industries

For years, we have specialized in addressing the unique challenges of bulk material processing, catering to a diverse range of sectors. Our expertise spans:

○ Mining: Handling raw minerals, ores, and aggregates with robust, wear-resistant equipment.

○ Cement Industry: Supporting cement production workflows with reliable material transfer and processing solutions.

○ Energy & Chemicals: Managing hazardous or sensitive bulk materials (solids and solid-liquid mixtures) with precision and safety.

○ Food Industry: Delivering sanitary, compliant systems for food-grade bulk material handling, adhering to strict industry standards.

By integrating key processes like conveying, crushing, mixing, and screening into unified solutions, we eliminate inefficiencies in fragmented workflows, helping our clients reduce operational costs and improve productivity.

The New Tracked Conveyor: Designed for Cost Savings and Versatility

Our newly launched Tracked Conveyor is engineered to address a critical pain point for industries like mining and cement production: high costs associated with stockpiling bulk raw materials. As a CE-certified bulk material stacking conveyor, it combines high performance with compliance, making it a core equipment unit in our one-stop solutions. Its standout features include:

1. Exceptional Site Adaptability

Equipped with a tracked undercarriage, the conveyor excels in diverse and challenging environments—from uneven stockyards to busy ports. It navigates rough terrain with ease, eliminating the need for extensive site preparation and expanding its usability across different project locations.

2. Flexible Telescopic Adjustment

The conveyor's telescopic design allows for on-the-fly length adjustment, enabling precise control over material stacking and transfer distances. This flexibility ensures it can adapt to varying stockpile sizes and workflow requirements, reducing downtime and optimizing material handling efficiency.

3. Powerful Hydraulic System

A high-performance hydraulic station drives the conveyor's operations, delivering consistent power for smooth material transfer—even when handling heavy or dense bulk materials. The system is built for durability, minimizing maintenance needs and ensuring long-term reliability.

4. Safety-First Design

Safety is a top priority in our engineering. The Tracked Conveyor includes multiple safety features, such as emergency stop buttons, overload protection, and stable braking systems, ensuring compliance with global safety standards and protecting on-site personnel.

5. Global Transport Readiness

Designed specifically for container shipping, the Tracked Conveyor can be efficiently packed and transported to any location worldwide. This feature is a game-changer for our international clients, reducing logistics complexity and ensuring timely equipment delivery.

Your Go-To Solution for Bulk Material Transfer

Whether in ports, stockyards, mining sites, or cement plants, the Tracked Conveyor serves as a reliable “right-hand man” for bulk material transfer. It streamlines stockpiling processes, cuts operational costs, and integrates seamlessly with our existing bulk material handling systems—from pneumatic conveyors to crushers—creating a fully optimized workflow.

Get Detailed Technical Specifications

For detailed technical parameters of the Tracked Conveyor—including load capacity, conveyor speed, telescopic range, and hydraulic system specifications—please contact our CAFU Service Team. Our experts will provide personalized support, helping you determine how this equipment can enhance your specific bulk material handling operations.

Contact us today to learn more about the Tracked Conveyor and our full range of one-stop bulk material solutions.

With a focus on quality, compliance, and client-centrism innovation, we serve industries including mining, cement, energy, chemicals, and food, delivering equipment that drives efficiency and cost savings worldwide.